KNOLL: With INNOZL coolant nozzles against grinding burns

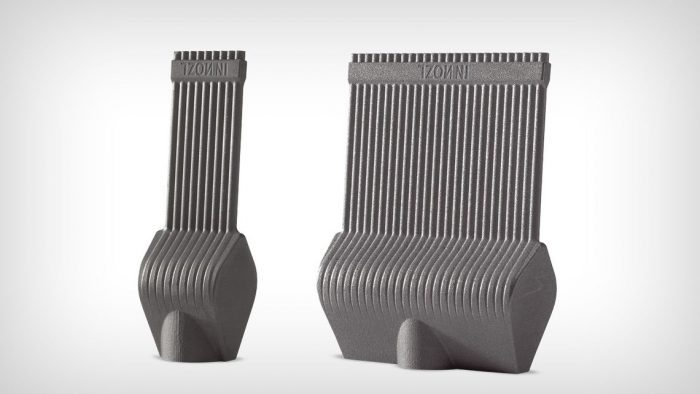

KNOLL will take over the complete product range of INNOZL™ coolant nozzles from the Dutch company INNOGRIND on 1 October 2021. The 3D-printed grinding nozzles made of titanium or stainless steel were specially developed for cylindrical, surface and centreless grinding and reliably prevent thermal damage during the grinding process.

KNOLL Maschinenbau GmbH, Bad Saulgau, is one of the leading suppliers of equipment for grinding machines with its conveying and filter systems for chips and cooling lubricants. Matthias Knoll explains: “With our proven aggregates that accompany the machining process, we ensure the best grinding results and, in particular, high process reliability. By taking over the INNOZL™ coolant nozzles, we are continuing our commitment in this regard directly to the machining process.”

KNOLL has been in contact with Jos van Langh, the founder and owner of Innogrind B.V., for years. The common theme has always been grinding technology, with which Jos van Langh has been intensively involved for over 40 years. In addition to his consulting work for various companies, he developed specially designed coolant nozzles against the dreaded grinding burn at the request of his customers.

3D-printed from titanium or stainless steel, these INNOZL™ nozzles are superior to conventional plastic products in many respects: The geometry of the internal flow channel ensures that the coolant always reaches the contact zone consistently, both in terms of flow rate and flow speed and direction. This maximises the lubricant effect and reliably prevents thermal damage to the workpiece. Flow analyses are used to check and optimise these properties with every new development. One resulting advantage: the nozzles work largely loss-free, which means that the required flow rate is lower and energy is saved.

In addition, the titanium and stainless steel nozzles are much more resistant than their plastic counterparts and are also suitable for high-pressure applications. This means they can also be used as cleaning nozzles for ceramic CBN grinding wheels. Their compact design is another strength. This means they can be easily mounted on existing cooling systems as a one-piece accessory.

“The INNOZL™ coolant nozzles are an ideal addition to our product range,” emphasises Matthias Knoll. On the one hand, they are offered as standard INNOZL™ SL products from stock. On the other hand, KNOLL develops customer- and process-specific INNOZL™ CL variants. The company can continue to count on Jos van Langh, who in future will also act as KNOLL area sales manager for the BeNeLux region.

For more information, please visit: https://www.knoll-mb.de/en/news

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech