HEULE: Automated Deburring of Cross Bores

Photo by Heule Werkzeug AG

From mechanical engineering and process engineering to aircraft construction and fluid power technology, these industrial sectors rely on highly complex machines and systems built from diverse components. Manufacturers often depend on external partners with specialized expertise, such as Knoepfel AG from Walzenhausen, Switzerland. With a team of around 50 employees, Knoepfel AG specializes in producing complex, high-precision mechanical components. Its process-oriented approach and “zero error” philosophy make it a leader in series production while remaining capable of handling small batches and custom parts.

Over recent years, Knoepfel AG has evolved from a small workshop into one of Europe’s leading manufacturers in its field. This transformation is ongoing, as the company continues to streamline processes, enhance its services, and invest in automation and cutting-edge production technologies. These advancements enable Knoepfel AG to deliver reliable, cost-effective solutions even for the most demanding high-precision applications.

Application-specific deburring tool as a solution

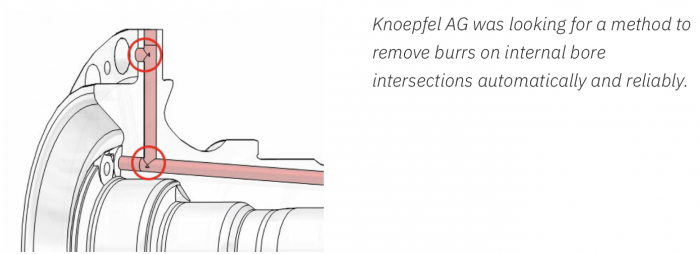

Such a strategy was required some time ago in the production of a wheel bearing made of high-tensile steel. A convincing machining concept was quickly presented to the customer, whereupon production of the hundreds of components per year was started. After a few months, Knoepfel AG recognised further automation potential. The workpiece has intersecting cross bores with a diameter of 7.0 mm.

Until now, the resulting burrs on the internal bore intersections were being removed manually with deburring scrapers and brushes, which was extremely time consuming. In the future, this process step must be fully automated so that the high-precision components will come off the machine completely finished and burr-free.

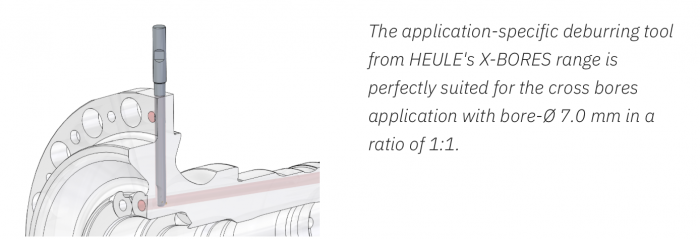

Knoepfel already uses mechanical deburring tools from HEULE Precision Tools for various other applications. The official representative of HEULE for the Swiss market, Eisenbart GmbH, was consulted about the feasibility of automatically deburring the cross bores. Thomas Eisenbart accompanied Knoepfel AG closely during the application analysis and coordinated a visit to HEULE’s production site in Balgach, during which not only the various deburring options were presented, but also the first tests were carried out with the COFA-X tool from the X-BORES series. This tool concept is always customised by HEULE to suit the specific application requirements of the customer. It is suitable for intersecting bores with a main bore to cross bore ratio of 1:1, as well as for applications with axial offset.

Time saving of 12 minutes per part

During the initial tests at HEULE, it became apparent that the workpiece material itself presented the greatest challenge, as the surface of the material hardens due to the heat produced during cutting. These tests resulted in modifications to the tool, after which Knoepfel carried out further testing in its own factory. The deburring results achieved were met with great enthusiasm, a high quality and process-stable solution had finally been found. The X-BORES tool has now been fully integrated into the series production.

By eliminating the time-consuming manual deburring, up to 12 minutes are saved per workpiece, which amounts to around 280 hours per year based on a production quantity of 1,400 workpieces. The elimination of manual deburring also enables reallocation of the employee’s skills to carry out more valuable tasks. Daniel Boehrer, CNC turning specialist at Knoepfel, is also impressed by the new solution and especially by the long blade life: «I always check the tool after about 300 parts. Most of the time, it shows that the blade is still working perfectly.»

Thomas Dietsche, Head of Production and Technology at Knoepfel, is particularly pleased with the stable and reliable process: «We no longer have to worry about annoying burrs remaining and can focus our attention on other challenges.» The entire Knoepfel AG team also appreciates the personal and professional support provided by Thomas Eisenbart, CEO of Eisenbart GmbH, who not only coordinated the entire enquiry process between HEULE and Knoepfel, but also supported with his technical knowledge of the HEULE tools in case of questions. For example, during the photo shoot for this article, Thomas advised Knoepfel’s employees in a very uncomplicated and spontaneous manner on the use and optimisation possibilities of the HEULE tools already in use. Just as a partnership should be: close to the customer and always solution-orientated.

For more information, please visit: https://www.heule.com/en

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech