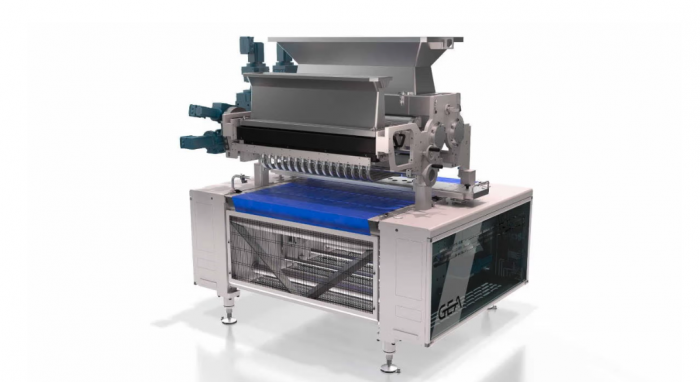

GEA Launches New High‑Speed Bake Extruder for Modern Biscuit Production

Photo by GEA Group Aktiengesellschaft

GEA introduced its new high‑speed Bake Extruder at IBA 2025 in Düsseldorf, Germany. Engineered specifically for medium to large-scale biscuit and cookie manufacturers, the system addresses rising demands for speed, flexibility, and hygiene in industrial baking operations.

Design and Production Capabilities

The modular extruder supports multiple production styles—including wire‑cut, co‑extruded, filled, continuous extruded, and deposited formats—enabling production of a wide variety of cookies, bars, and biscuits with varied textures, fillings, and inclusions.

Its wire-cut system operates up to 350 strokes per minute across a working width of up to 1,700 mm. For specific formats, it achieves 130 cuts per minute for encapsulated cookies and up to 250 cuts per minute in continuous extrusion mode.

Precision Control and Custom Dosing

Driven by brushless motors and servo-driven axes, the extruder offers refined control over extrusion speed and cut timing—ensuring consistent product shape and size even at high throughput. Optional lobe pumps enable precise dosing of aerated or inclusion-heavy doughs, preserving product integrity.

Operator-Friendly Interface and Hygiene Standards

The system features a new HMI control unit offering intuitive operation, multi-level access, ERP integration, and predictive maintenance capabilities. Its hygienic design includes a removable hopper, open‑head layout, photoelectric safety barriers, and stainless steel components for easy cleaning and compliance with food safety standards.

Customer‑Driven Innovation

Development of the Bake Extruder was guided by in-depth customer interviews and market research. GEA’s Application Manager Matteo Pasquali explained that industry demands for higher performance, versatility, cleaning ease, and expanded product variety directly shaped the design.

Why the Bake Extruder Matters for Industrial Baking

The GEA Bake Extruder offers:

- Exceptional throughput: up to 350 wire‑cut strokes per minute

- Flexible configuration for different product types and dough textures

- Accurate extrusion and cutting control for consistent quality

- Enhanced sanitation and operator safety

- ERP-compatible interface for streamlined production workflows

This makes it an ideal solution for operators seeking to scale production efficiently without compromising on hygiene or diversity of baked goods.

For more information please visit: https://www.gea.com/en/company/media/press-releases/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech