Kapp Niles Enables Precision Wind Turbine Gear Grinding with Ott Zahnradfertigung

Zahnradfertigung Ott, a trusted supplier for wind turbine ring gears up to 2,500 mm diameter—including internal gears—relies on Kapp Niles’ ZP I/E profile grinding machine. Its robust design and oversized grinding head ensure top-notch precision.

High Expertise Meets Advanced Machine Technology

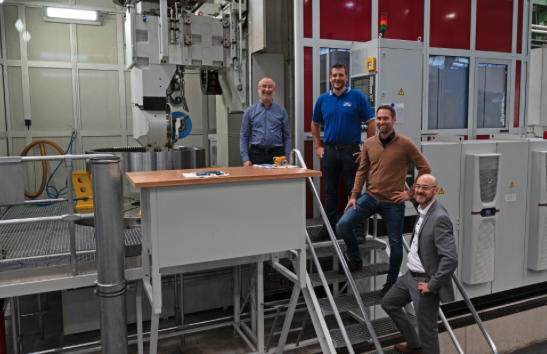

Ott’s team—including Siegfried Nill, Roland Löffler, and Jens Haag—worked closely with Kapp Niles experts like Markus Reißenweber to produce complex gears with minimal tolerance margins. The ZP I/E machine enables highly accurate finishing of large components under challenging conditions.

Supporting the Wind Power Industry Transition

With 80 % of modern turbines using gearboxes, rising turbine power and torque levels demand precision gear finishing. Kapp Niles offers integrated gear grinding and measuring solutions tailored for wind power needs.

Complete System Coordination for Optimal Quality

Kapp Niles provides a full precision system—machines, dressing tools, and measuring units—ensuring consistent gear surface quality. Machines like the ZP series and measuring machines for diameters up to 6,000 mm improve throughput and accuracy.

Innovations for Efficiency and Reliability

To reduce setup times and avoid errors, Kapp Niles developed features such as wobble compensation and automatic tool-changing. These enable high-quality finishing with surface roughness as low as 0.2 µm, even under high productivity demands.

Towards a Sustainable Future in Wind Energy

By aligning engineering, measuring, and automation, Kapp Niles supports gearbox producers in delivering reliable, efficient wind power components—strengthening renewable energy infrastructure worldwide.

For more information please visit: https://www.kapp-niles.com/en/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech