BIG KAISER C-Cutter Mini reduces up to 85% of machining times

Photo by BIG KAISER Precision Tooling Ltd.

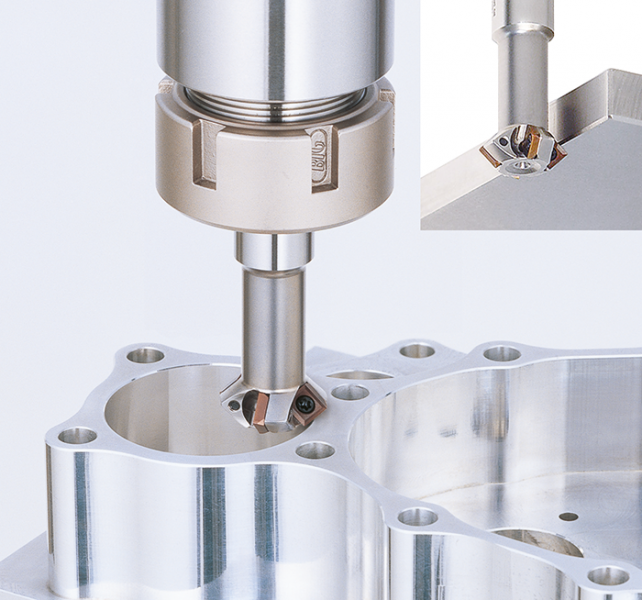

BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metal-working industries, announced the C-Cutter Mini, an ultra-fast compact chamfer cutter.

The C-Cutter Mini is designed for multi-functional cutting tasks, including chamfering, back chamfering and face milling. Compared to competitors’ products, the tool’s market-leading speed and feed rate capability has the potential to slash machining times by up to 85 per cent.

The tool’s innovative design reduces the cutting diameter down to the lowest limit, enabling impressive ultra-high spindle speeds and feed rates. Cutting speed is further increased by new wear-resistant inserts with multi-layer Physical Vapour Deposition (PVD) coating.).

Available in single insert and four insert configurations, the C-Cutter mini thereby provides additional flexibility to the customer. Increasing the number of inserts from one or two per cutter to four, multiplies the feed rate, which speeds up operations and improves productivity.

BIG KAISER is also introducing the world’s smallest hex insert, with a diameter of 3.97mm. This enables highly-efficient back chamfering from a 6mm starting hole diameter, whilst the 3-corner insert design reduces costs.

“The new C-Cutter Mini delivers a ‘triple effect’, essentially compounding the benefits of the tool’s four inserts which deliver faster feed rates, its reduced diameter which raises the spindle speed, and the new PVD coating which enables higher cutting speeds,” says Giampaolo Roccatello, VP Sales at BIG KAISER. “This tool is a prime example of how BIG KAISER’s focus on innovation consistently delivers tangible results to our customers.”

For more information, please visit http://kaisertooling.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech