FANUC launched a new dedicated IoT area for Technology Day at its Ansty Park headquarter

FANUC unveiled a new space dedicated to the Internet of Things (IoT) at its UK headquarters in Ansty Park, Coventry, as part of its latest Technology Day for Wire EDM.

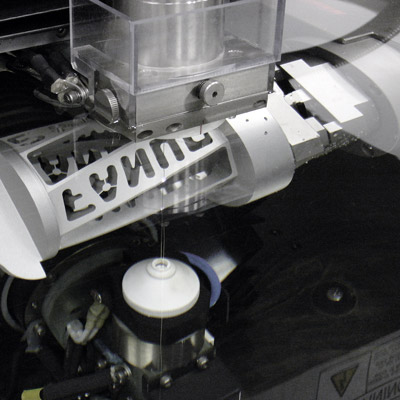

The day saw several of FANUC’s state-of-the-art ROBOCUT α-CiB Wire EDM machines in live-cutting action. What’s more, all production data were available to view in real-time in the new IoT area, as the space demonstrated FANUC’s out-of-the-box MT-Linki machine tool monitoring service, which allows users to remotely monitor, harvest and analyse live production data.

Visitors were also able to get a first glimpse of FANUC’s newest data connectivity platform, FIELD, will fully launch later in 2019.

FANUC’s α-CiB machine series comprises of compact, high-performance submerged wire-cutting machines with high rigidity and cutting accuracy. One of the stand-out features of the range is the built-in CORE STITCH function, which allows operators to extend unmanned machining hours by the better planning of cutting jobs. Stitch points are set directly on the machine’s CNC without the need for any pre-programming, and when used in combination with the wire path re-threading function, it offers the ideal solution for long-lasting unmanned machining and multi-workpiece cutting. Once the job is complete, operators simply knock-out the cores by hand, avoiding any risk of damaging the machine.

The α-CiB machine series also employs FANUC’s AWF2 Automatic Wire Feed threading technology to provide fast, reliable automatic threading in just 10 seconds. Unlike other machines, the ROBOCUT series does not need to return to the starting point after a wire break, which radically reduces cycle times. To guarantee reliable threading and re-threading, wires are electronically cut to leave a pointed end which is truly straight and burr free.

Improved cutting control can also be achieved via the built-in iPulse 2 cutting function, which provides highly accurate corner control, regardless of material thickness or surface roughness.

One of the stand-out programmes which was demonstrated at the Technology Day was the Polycrystalline Diamond (PCD) cutting function. The α-CiB series takes PCD tool making a to a new level thanks to the ROBOCUT PCD Generator, which ensures that the crystals remain intact during the cutting process. It provides high-speed precision machining for tool sharpening and makes it possible to process extremely difficult to cut PCD and CBN grades. Furthermore, FANUC ROBOCUT is available with a CCR rotary table, which improves cutting complex PCD tools through high-resolution glass scales.

As well as the new IoT area and dedicated Wire EDM demonstrations, visitors to the Technology Day were also able to see a host of other FANUC production machinery, including models from its ROBOSHOT injection moulding series, ROBODRILL compact 5-axis CNC machine tool series, as well as a number of models from its broad portfolio of industrial robots.

For more information, please visit http://www.fanuc.eu.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech