FOOKE FSW machines – Friction stir welding machines from the Münsterland

The traditional company FOOKE GmbH in Borken, which is still managed by the owner family, the Fooke family, has expanded its portfolio of machine tools to include friction stir welding systems, FOOKE FSW systems.

For many years FOOKE concentrated on the conception, design and manufacture of large, precise and highly dynamic portal milling machines. These are used in demanding applications such as aerospace, automotive, commercial vehicle and rail vehicle construction, model, prototype, tool and mould making.

Friction stir welding, or FSW for short, has been gaining in importance for some time, particularly in the manufacture of aluminium components and assemblies: The material is not melted at the joints during friction stir welding – as is the case with conventional welding – but rather is literally “stirred” under high pressure.

Particularly in friction stir welding of aluminium, the hot cracking problem and the formation of pores due to the absence of a liquid or vapor phase in the material does not occur. Shielding gas or other filler materials are not required. Foreign alloying elements do not get into the weld seam; all factors which ensure welds of very good quality with high and homogeneous strength.

Further advantages of friction stir welding briefly described:

Friction stir welding can be used to join different materials, such as aluminium with steel, and even some materials that do not form an alloy can be joined together.

Although the FSW process develops temperatures of approx. 500°C when joining aluminium, this is considerably less than with conventional fusion welding. This results in significantly less welding distortion of the workpieces.

A special weld seam preparation is usually not necessary even with thick wall thicknesses of the workpieces to be joined. Only a stable base and a solid fixation during the FSW process are fundamental.

Friction stir welding is suitable for the joining of thin-walled sheets as well as for example 50 mm thick plates. The sheet thickness and also the feed speed for friction stir welding depends fundamentally on the machine tool used. The axial force that the machine is able to exert is of utmost importance.

FOOKE has now produced large and very large FSW systems for various applications. In many cases explicitly at the customer’s request. They are primarily used for joining large assemblies made of aluminium hollow chamber profiles. Others, with up to 150 kN axial force, which corresponds to approx. 150,000 kg, for welding thick plate material.

Now FOOKE has initially developed three standardised machine tools for various friction stir welding applications, primarily for joining aluminium sheets with thinner wall thicknesses:

The friction stir welding machine FOOKE FSW 10 is virtually an “entry-level machine”. This universal 3-axis machine was specially designed for welding workpieces with a length of 2,000 to 10,000 mm. With an axial force of 50 kN, approx. 5 tons, workpieces made of a 6XXX aluminium alloy with a wall thickness of up to 20 mm can be welded, for example.

A friction stir welding machine FOOKE FSW 20 can be used primarily to weld sheets together. This machine tool is designed for sheets with a width of up to 3,900 mm. The sheets to be welded can be positioned on the machine in a particularly ergonomic manner, as the FSW spindle and its travel axes are integrated into the machine table. Welding takes place virtually from below.

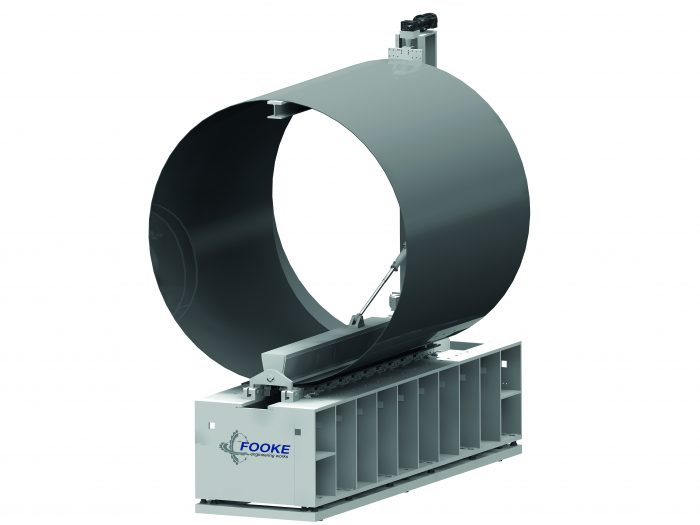

A friction stir welding machine FOOKE FSW 30 was developed for welding small and large cylindrical segments with a diameter of up to 2,600 mm. Like the FOOKE FSW 20, this machine also has an axial force of 50 kN.

Further standardised friction stir welding machines are planned. FOOKE continues to be recommended as a partner for special solutions on customer request.

For more information, please visit: https://www.fooke-portalfraesmaschinen.de/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech