Future-proof production with Turn & Mill expertise from Bielefeld

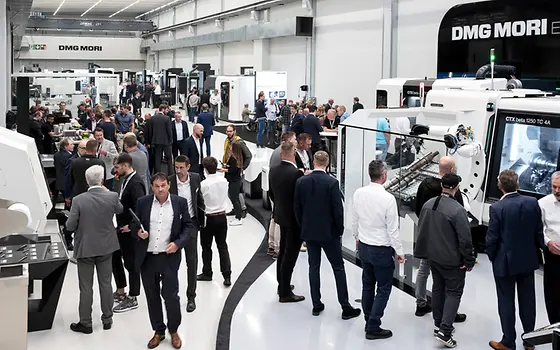

At this year’s in-house exhibition in Bielefeld, DMG MORI will be providing insights into the world of modern machine tool technology and an outlook on the production of the future. From May 20 to 23, 2025, the traditional plant and Turn & Mill Competence Center will open its doors to present 21 high-tech machines and their functions in the context of Machining Transformation (MX) on an exhibition area of around 1,600 m².

Highlights of the exhibition include the NLX 2500|700 2. Generation with CELOS X, the CTX beta 450 TC with integrated loading and unloading device and the DMU 60 eVo 2. Generation for highly dynamic 5-axis simultaneous milling. In addition, numerous automation solutions will be on display, including the Robo2Go in various versions, the PH Cell 800 modular pallet handling system and the WH Cell 25 as a flexible workpiece handling system. DMG MORI will round off the program of its in-house exhibition with exciting presentations and workshops on pioneering trends in process integration, automation and programming. Plant tours through the Turn & Mill assembly also offer an exclusive look behind the scenes of the traditional plant. DMQP partners such as HAIMER, Fuchs, Horn and SolidCAM will inform visitors about their innovative solutions for the entire periphery of machine tools.

Tradition and progress in Bielefeld: Innovative turn & mill solutions for the future

DMG MORI Bielefeld has long since developed into a competence center for turning and milling within the Group. A well-thought-out product portfolio impressively underlines this position. The CLX TC series offers an easy entry into turn-mill machining with the well-known B-axis factor – a clear added value compared to conventional turret lathes. The CTX TC models go one step further: with 360° technology integration at the highest level, they enable turning, milling, gear cutting, grinding and measuring in one work area. This is complemented by powerful 5-axis simultaneous machining. The Bielefeld site is also a driving force when it comes to automation: the Robo2Go series offers a flexible and intuitive automation solution for small and medium-sized batches. Digital tools are increasingly becoming the focus of integrated manufacturing solutions. 3D Shopfloor Programming, OP Workbench and numerous exclusive DMG MORI technology cycles simplify the creation of sophisticated NC programs – efficiently and practically.

As DMG MORI’s traditional production site, Bielefeld offers the perfect environment for an in-house exhibition that shows much more than just modern machine tools. The focus here is on personal exchange: experts from development, sales, service and, of course, application technology are available to customers for intensive discussions – to answer questions, think ahead with ideas and open up new perspectives. “Our aim is not just to present innovations, but to work together with our customers to develop the best solutions for their production,” emphasizes Harry Junger, Managing Director of DMG MORI Bielefeld. “That’s why we see the in-house exhibition as an ongoing invitation – for continuous dialog and constant inspiration.”

For further information visit: https://en.dmgmori.com/news-and-media/news/nws2553-oh-bielefeld

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech