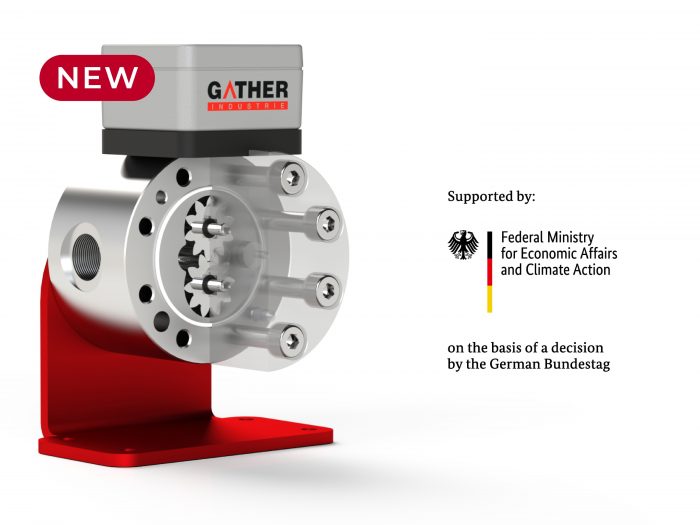

GATHER Gear flow meter – precise measurement technology for non-lubricating liquids

The GATHER gear flow meter (ZDM) is a volumetric flow meter based on the gearwheel meter principle for particularly non-lubricating, low-viscosity and chemically aggressive liquids. The movement of the gears is detected by a sensor via the individual gear teeth, in the form of pulses, contactless and hermetically decoupled. The GATHER ZDM is based on the same technology as the GATHER gear pumps which have seen decades of use in a wide variety of industries (including chemicals, pharmaceuticals, food, medicine, etc.).

The high-performance materials used in the ZDM (housing, shafts, gear rims, seals), the implemented fluid mechanics, the optimized tribology (channeling, plain bearing technology, etc.) as well as the precision of the components are based on a technology that has been tested and proven in well over 1000 different applications. Thus GATHER ZDM – just like the GATHER gear pump – is a robust and durable solution for the customer.

If aqueous liquids are conveyed, there are no dead zones in the measuring device. This effect can be utilized for cleaning in place (CIP) with a solvent or cleaning agent.

With the right design in terms of materials selection, we find the solution that enables our customers to work with process reliability. This also includes the design as a complete system with the corresponding control circuit and accessories in accordance with the customer specifications. Special solutions are our specialty. This also includes the use in potentially explosive atmospheres in compliance with ATEX directives.

Software functionalities

The GATHER ZDM has variably adjustable software functions for simple and precise use. A great unique feature is the calibration factor because the latter remains the same over the entire measuring range and thus delivers highly accurate results. This also applies in the event of exchange for a replacement device or after a recalibration. The calibration factor always remains constant! This functionality ensures a user-friendly and simple process integration.

The universal controller for all pump and control circuits

With the metering box 5000, GATHER supplies the appropriate evaluation electronics for the gear flow meter. By combining it with GATHER’s own universal controller, a control circuit can be set up with any suitable, pulsation-free pump, which can be integrated into any PCT. The metering box with integrated, universal PLC enables precise conveying, metering or filling at the touch of a button. The simple interface operation enables a quick activation of a wide variety of metering and measuring tasks. After entering a few parameters of the measuring sensor, the controller parameters are identified automatically within a few seconds.

Use in all sectors of industry – GATHER has the solution!

GATHER products are used in almost all sectors of industry. Wherever precise delivering, measuring, dosing or coupling of fluids matters. Whether lubricating or non-lubricating, whether low-viscosity or viscous, whether pump, flow meter, complete system or coupling. Our engineering is your solution!

For more information visit gather-industrie.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech