New GEA Akwatopsoft mattress system convinces in practice

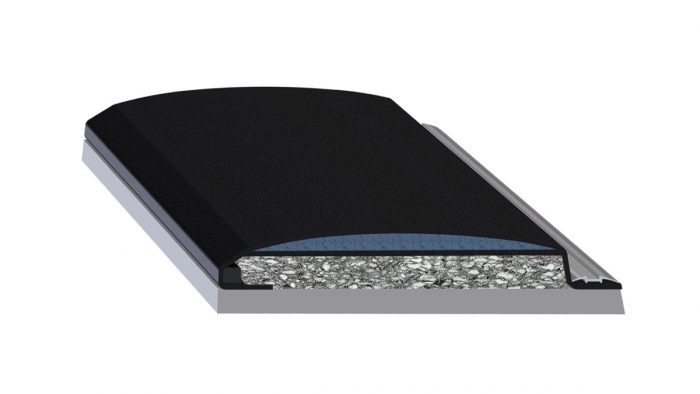

GEA Akwatopsoft system combines a 40mm foam matress with a water bed layer.

Photo by GEA Group Aktiengesellschaft

For dairy cattle there is already a wide range of lying facilities. These range from organic bedding materials to foam mattresses and waterbeds, with each system offering certain advantages. With the new Akwatopsoft, GEA now offers farmers a first-class mattress system for free-range housing that combines the advantages of lying systems.

A 40 mm thick foam mattress with a waterbed overlay provides 70 mm of comfort, which encourages cows to lie down for longer periods, contributes to animal health and ultimately increases milk production.

The Akwatopsoft system consists of a mattress made of 100% PU foam, which is enclosed in a highly resilient foil. A long waterbed support with separate chambers is attached to it, a roll length is enough for up to 50 meters. The support is available for lying surface widths of 115, 120 and 125 cm. The selection of the robust and reliable components used is based on GEA’s many years of experience with mattress systems and has already shown the first positive effects on the cows that can bed on the Akwatopsoft system in the loose housing.

Farmer Frank Boks runs a dairy farm with over 200 cows in Biddinghuizen (Netherlands) together with his parents. He explains why he chose the Akwatopsoft mattress system in combination with GEA’s Combi Comfort cubicle: “We already had experience with the waterbed. The disadvantage of this is that the cows push the water aside when they lie down, which means they end up on the concrete. With the new Akwatopsoft mattresses this does not happen. The cubicles have also become softer and the cows feel more comfortable,” says Boks. “We are already noticing that the cows go straight into the cubicle, lie down immediately and actually don’t touch the partitions of the cubicles. This means that there is no manure in the cubicles, for example,” says Frank Boks about the advantages of Akwatopsoft in terms of hygiene and increased lying time in the cubicle.

The foam mattress offers the cows a high level of comfort during their resting phases, a very good grip when getting up and lying down and is also easy on the hocks. The waterbed adapts to the cow’s body conditions by absorbing heat and cooling. Overall, the cow’s resting time is extended – an important goal for farmers who want to increase their milk production. In this relaxing position, blood circulation and rumination activity of the cow are promoted. When not in use, the mattress curves upwards again, so that, for example, leaked milk can drain off easily, which improves hygiene in the cubicle.

Together with the Combi Comfort cubicles and the new Akwatopsoft mattress system, Frank Boks uses other proven GEA components in his dairy farm. These include the VCool silo tank for milk cooling with heat recovery, CowScout for monitoring animal health and oestrus detection and three GEA DairyRobot R9500 milking robots. “In terms of comfort for the farmer and the cow, our barn is equipped for the future and we will enjoy our work in the coming years”, Frank Boks is convinced.

For more information, please visit: https://www.gea.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech