Gebau Kunststoff purchases Nordson’s SmartGap™ Sheet Die

Photo by Nordson Corporation</>i

In accordance with an agreement reached during the recent Interplastica show in Moscow, Gebau Kunststoff has purchased from Nordson Corporation a sheet die with a fundamentally new adjustment mechanism that makes changes in thickness with unprecedented speed and extends the range of thicknesses that can be produced.

The new EDI® SmartGap™ die will be installed in a Gebau Kunststoff production line in Moscow, along with two of Nordson’s BKG® high-pressure melt pumps, whose improved capacity will accommodate the greater range of thicknesses which the new die makes possible. Gebau will use the die to manufacture heavy-gauge sheet for packaging, furniture, and appliance applications.

Gebau technical director Grigorii Mulevan cited increased uptime and enhanced quality as the reasons for choosing the new die. “The SmartGap die will enable us to make faster changeovers over the whole range of thicknesses without interrupting production, and in the process reducing the volume of scrap generated during the translation from thin sheet to thick,” said Mr. Mulevan. “It will also help us to improve the quality of our finished product, enabling us to produce sheet with greater uniformity and flatness.”

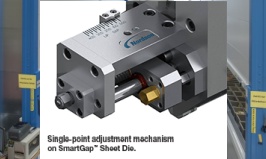

The patent-pending Smart-Gap system uses a single-point adjustment mechanism that changes the lip gap while modifying the length of the lip land at the same time to give the most ideal conditions for the newly adjusted thickness as the sheet exits the die. The lip land is the final gap in the die that forms the lip exit. By mechanically linking the adjustment of these two key process variables for the first time, the SmartGap system provides a proper set-up of the die and takes substantial time and guesswork out of the process for achieving desired sheet properties.

The SmartGap system, available only on new dies, eliminates the extended shutdowns for changes in lip components that have often been necessary when transitioning to new job runs, reducing to a matter of a few minutes changeovers that used to take two hours or more. Also overcome are previous limitations on thickness range caused by the complexities of die modification; the SmartGap system readily encompasses die gap adjustments over a range of 27 mm, enabling processors to efficiently run with multiple product changes per day. At the same time, the SmartGap system enhances product quality and consistency, in part by keeping the lip faces and lip lands parallel while carrying out changes in thickness.

For more information visit: http://www.nordson.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech