Hainbuch clamping devices provide the right solutions for KTR Group

The Hainbuch mini chucks keep to their promise.

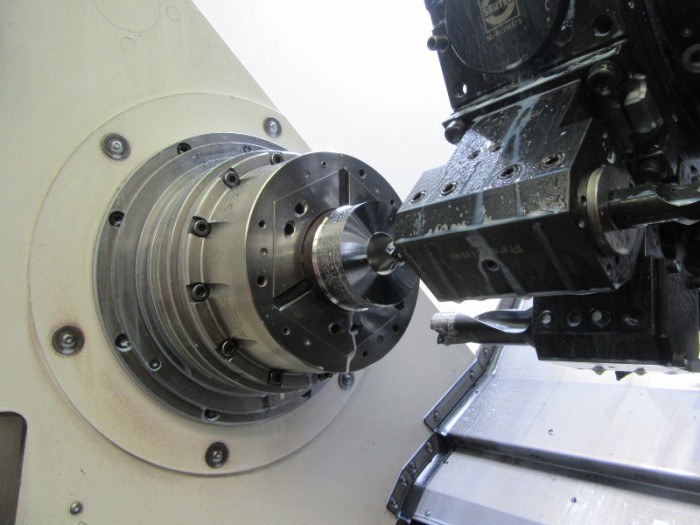

Photo by HAINBUCH

Off to new horizons – with new machines, shorter processes, and a new workholding technology at the KTR Group in Rheine. During the periodic replacement of the machines the clamping devices were also questioned. The requirements were significant improvements in set-up times and in the manufacturing process for handling chips and contamination. Some cases had negative effects on the appearance of the workpieces. EMO 2013 was soon to take place in Hannover where the responsible persons wanted to get an overview of the market and the possibilities. At this point in time there had not yet been any contact with Hainbuch as a manufacturer of the clamping devices. However, at the exhibition, it quickly became clear that the right solutions could be found from Hainbuch. In the meantime, KTR and Hainbuch had become close partners and had successfully optimized manufacturing step-by-step. The Hainbuch clamping devices had completely satisfied the requirements and offer additional advantages.

KTR is pursuing a course of growth and optimization

The family-run business with high-level research and development competence, which specializes in couplings, brakes, coolers, and hydraulic components for industrial applications, imposes the most rigorous requirements on itself and on its suppliers. The most rigorous requirements particularly apply for the core business, couplings with diameters from 10 millimeters to two meters. Close tolerances and outstanding concentricity properties are demanded. Matthias Telker, Director of Production Management at KTR, is responsible for process optimization at all manufacturing locations. Telker states: “To obtain the maximum, to deliver permanent quality of premium products, as well as being successful internationally. Constant improvements in all areas are unavoidable.” KTR supplies companies around the world in the following industries: railway and transport, agricultural and construction machines, machine tools and automation, wind power, and is increasingly supplying companies in the areas of marine engineering, smelting and foundry technology.

Off to new horizons

In 2013 there were extensive upheavals in manufacturing. The stipulations were to reduce idle and set-up times in production in order to further optimize throughput time. Consequently, Günter Schleyer, Production Manager at KTR, was intensively involved with this topic. “Several machines were due to be replaced after reaching the limit of their service life. Therefore, we re-examined the clamping area. The important questions for us were: How will we position ourselves in the future, and how do we increase flexibility? Among other things we use machines in floating processes for both series and single-item productions. Here we were at a crossroads: On one hand we required a specialized series production, and on the other hand we needed a fast, flexible cell for the single parts.” His colleague, Production Manager Franz-Josef Reder, was assigned to deal with the new clamping system. In his research Reder then encountered the clamping devices from Hainbuch. The visit to the Hainbuch exhibition booth at EMO followed.

From presentation to rental, from rental to purchase

KTR requested that the responsible Hainbuch Outside Sales Representative, Rudolf Meyer, came to Rheine. Meyer sat down at a table together with both Schleyer and Reder, as well as employees from the manufacturing and design departments and checked which clamping devices could fit with KTR products. However, to become thoroughly acquainted with the products, test their handling, and to see whether the employees could exploit the potential of the clamping devices, the company opted for Hainbuchs rental offer. “By the way, the rental was a great thing”, adds Telker. Early in 2014 KTR received the Torok manual chuck with a base plate, a clamping head, and a mandrel for the trial phase. For Telker the overall time savings was extremely important. “How does the system perform in the daily routine? Is it rigid, and can it meet our practical requirements? Can we organize our set-up more efficiently with it? Of course the holding forces and repeatability were highly significant. This is where our manufacturing imposes very high requirements”, reports Schleyer and Reder. “Practical experience had shown us that conventional jaws were out of the question. For our coupling manufacturing parts are machined at high cutting speeds. Cams and bores are milled and drilled, so that we have a wide variety of chip shapes that must not impair the function of the clamping devices. The clamping device should be practically self-cleaning. Needless to say, the implementation of the Torok manual chuck on one of the milling machines of the production line past the test with flying colors. With these findings the green light was given for working together with Hainbuch. In addition, according to Schleyer there was the fact that the production employee must operate two machines. “Our machines must have certain synchronization in the runtimes. This is an absolute must, particularly for the multi-machine operation.” The result? One manual chuck does is not enough, more parts must be clamped. KTR returned the Torok that had been rented for test purposes.

Machines were changed over step-by-step

KTR ordered a clamping pallet with four Hydrok SE hydraulic stationary chucks in the hexagon version along with clamping heads and mandrels for the new machining center announced in 2015 from Hainbuch. Schleyer explains: “The Hainbuch system is custom-tailored for our products, particularly the flexibility of the clamping heads and mandrels. We do indeed use the clamping heads very intensively; however, we always have special components for which we use their mandrels. At the same time, right from the start we have also planned to use the Hainbuch clamping system for the turning machines that we ordered in 2015. Therefore we use the TOPlus mini chuck. We have a consistent system, whether for turning or milling. Now we are able to change within the modular system and therefore we are much more flexible.” Thanks to the new turning machines in relation with the new clamping tools, some coupling series can be completely manufactured in one clamping set-up. Reder recalls: “The new investments in the manufacturing are opening up entirely new possibilities for us in this area. Now we can bundle different machining steps and thus reduce throughput times.” Telker is also sure that the development will move forward in this direction. We save a lot of time and gain flexibility.

Advantages as far as the eye can see

In summary, for the KTR Group the expenditure has more than paid off. The required qualities can now be achieved with more simple means. The blanks are clamped in and you are ready to go. Re-clamping and intermediate measurements are unnecessary, and set-up times have been significantly reduced. It was even possible to reduce set-up times for multi-machining operation, and manufacturing processes are better synchronized. Moreover, the handling and reliability of the clamping devices have also shown impressive benefits at all implementation sites. Reder: “Use of the Hainbuch clamping systems was a real step forward. Manufacturing has been simplified, tolerances are perfectly complied with, and the shop floor has become leaner and more flexible.” Telker enthuses: “With the new clamping devices we have been able to gain larger advantages. Consequently, performance has increased substantially.” But what about the holding forces? Absolutely secure, even though we are machining at just 5 millimeters.

For more information, please visit http://www.hainbuch.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech