Heuer Präzisionsteile and EWS are jointly rethinking the manufacturing proces

Often reduced to classic feather key grooves, it is actually a highly precise, versatile machining process, especially if you think about it from the outset. This is precisely where the connection between Joachim Heuer, Managing Director of Heuer Präzisionsteile GmbH and founder of Heuer Radsport, and Matthias Weigele, CEO of tool manufacturer EWS Tool-Technologie, comes in.

Their collaboration did not arise from a glance at the catalog, but from real challenges in manufacturing issues and a shared desire not only to apply technologies, but to think them further.

After all, the use of technology begins much earlier: in development. Anyone who designs components without knowing the latest manufacturing technologies is not limited by the machines, but rather by their own horizons. Or as Joachim Heuer puts it from an application perspective: “You can only ask what you can imagine – and you can only imagine what you have already seen. “

Recognizing potential – and exploiting it right from the start

Many technicians immediately think of the classic keyway when they think of shaping, but this is only the simplest or even best-known application. Another example of an application is the production of an internal hexagon: “When a customer from the design department recently said: “That’s complex – free drilling the corners, circular milling 30 mm in depth, you can hardly get in that deep”, I had to smile. The component had long since been shaped in my mind – but this option didn’t even exist in his head yet, ” says Heuer.

Today, a contour during shaping is often only limited by how a shaping tool can be ground – and this applies to both the internal and external geometry. Matthias Weigele adds: “The process is suitable for any shape that has a groove character, and the geometry limits are not defined by the machine, but by the tool kinematics and the structure of the cutting edge.” This opens up scope for complex, economical machining operations that would often be costly or impossible to achieve with other processes.

Challenges in development

In practice, there is no “ideal geometry”. There are only geometries that can be produced better or worse under certain conditions. Anyone who integrates technologies such as shaping into their way of thinking shifts this boundary decisively, especially in the case of complex or recurring contours . “If I know that I can also shaping deep internal contours with sharp corners cleanly, then I design completely differently,” explains Joachim Heuer . “Suddenly, a seemingly difficult component becomes a task that can be solved perfectly and economically. “

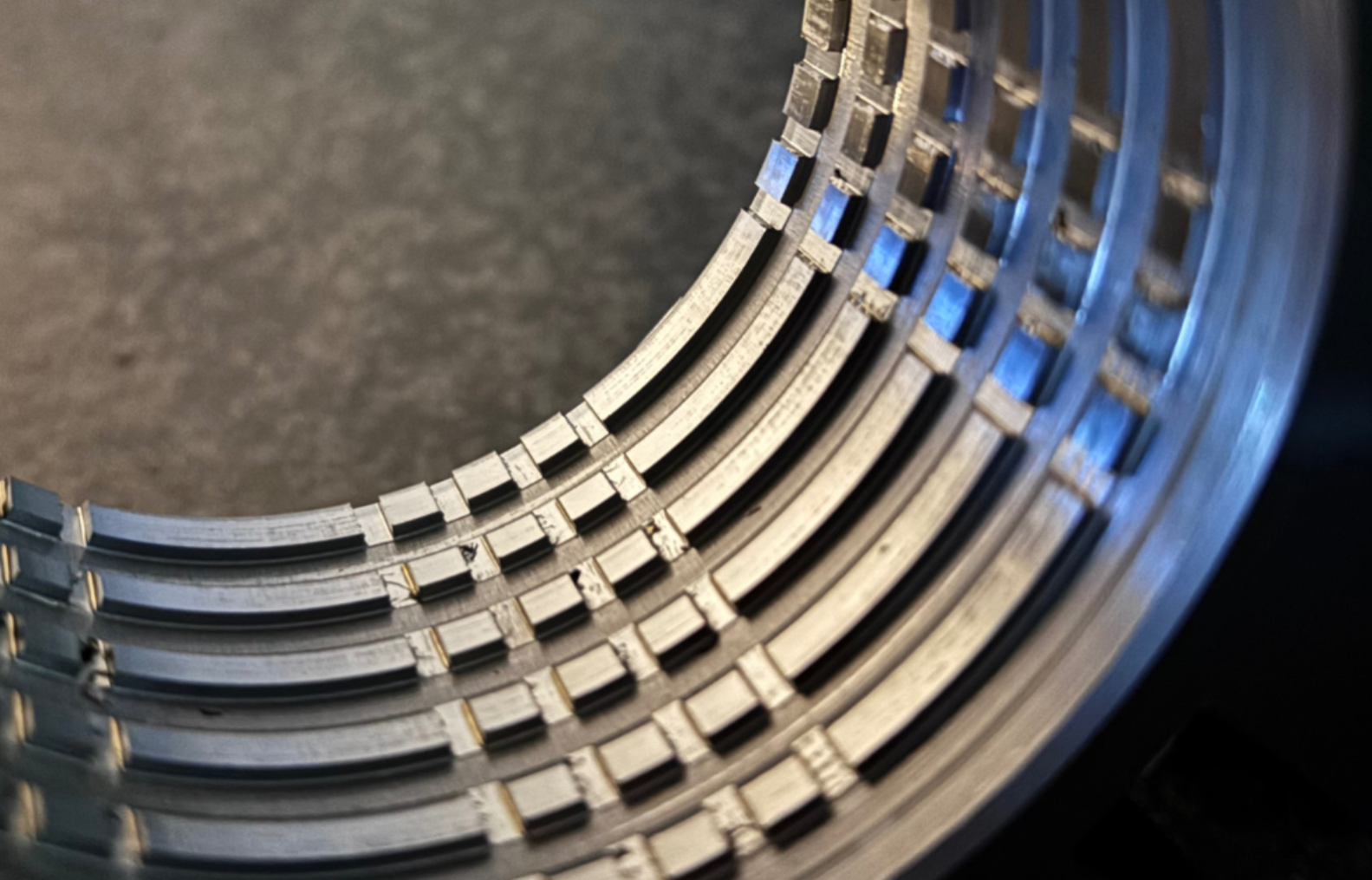

Recurring patterns, such as internal corners for square or hexagonal gears, splines and other positive-locking profiles, can be produced particularly efficiently with the shaping technology. Special shapes, where specific corners need to be cut out or defined radii produced – for example for position or sensor rings – can also be machined directly in a single clamping operation. This becomes economical with tools that have a contour machined multiple times. Instead of shaping 60 teeth individually, for example, a cutting insert can be produced for three tooth segments. The result: a third of the machining time. Design and costs are therefore directly related – those who design components with process understanding already decide on efficiency, runtime and cost-effectiveness in the design phase. The challenge therefore lies not only in the machinery, but in the approach.

For further information visit: https://ews-tools.de/en-DE/news/groove

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech