HWACHEON: Product news and innovations from South Korea

HWACHEON is one of the most traditional machine tool manufacturers in South Korea. The company has been producing in its domestic plants since 1952, making it the oldest manufacturer of turning and milling machines in the country.

As early as 1977, the company took over the pioneering role for future-oriented cutting machines with the first Korean NC lathe and has continued to expand its technological leadership over the decades – until today.

Tradition and innovation are not mutually exclusive, and so Hwacheon also holds on to the tried and tested with conviction – entirely in the interest of its customers: convinced of their reliability, precision and durability, the company continues to rely on flat guides scraped by hand and with the utmost care, heavy cast beds, state-of-the-art spindle technology, all from in-house production and all “Made in Korea”.

In 2019 and 2020, Hwacheon presented numerous highlights and added more models to the product range.

Vertical lathes now also with Y-axis

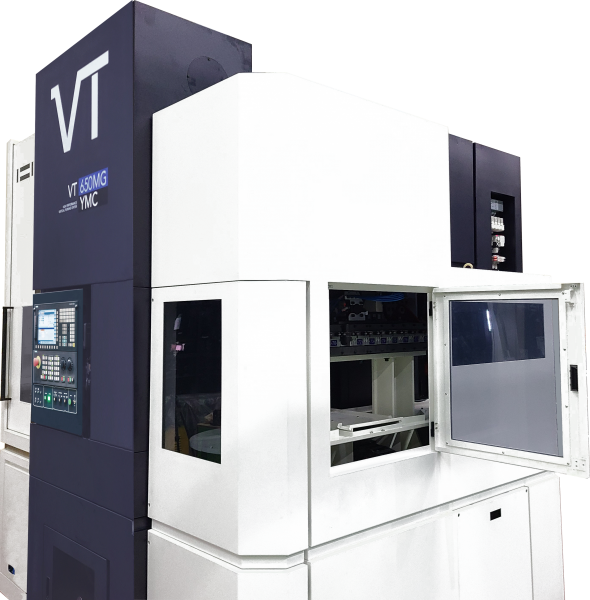

The VT series, consisting of five models, is in continuous use at many world-renowned companies and is one of Hwacheon’s most successful series, especially in Europe. Despite often harsh operating conditions, the vertical lathes are convincing in terms of precision and reliability. For this reason, they are used with great popularity in automated production lines, especially where difficult-to-machine materials are to be machined. The need for vertical lathes that can be easily linked in a line production of complex workpieces and that can cover both turning and milling operations was recently met by the company with a revised version of the VT-650, which has been available with a Y-axis (±125 mm) since the summer of this year. In doing so, Hwacheon traditionally relied on flat guides in all axes to achieve maximum stability and durability. The VT-650 is designed for workpiece diameters up to 700 mm and has a 12-position turret with BMT75 mounting. In addition, the machine can be equipped with a tool magazine with 16 or 48 places in order to slay as many operations per machine and clamping as possible.

The VT machines can be equipped with a spindle on the left or on the right side, in order to slay as many operations as possible per machine and set-up. For integration into production lines, the VT machines can be ordered with the spindle on the left or right side. In this way, the layout and material flow can be designed to be as efficient and space-saving as possible.

Addition to the Hi-TECH series

At the turn of the year, Hwacheon added another heavyweight to its series of flat-guided horizontal lathes. The new Hi-TECH 750 covers turning diameters up to 760 mm and is available in three different bed lengths (2 / 3 / 4 m). Numerous optimizations have been made, particularly with regard to stability. Already included as standard is the double-row BMT85 turret, on which tools can be mounted with two holders per station. In this way, particularly long tools used for drilling and internal machining are ideally supported and vibrations are significantly reduced. Numerous optimizations have also been made to the headstock, which accommodates the two-stage gearbox. The bearing diameter was increased to 240 mm and can withstand the highest loads in continuous operation. Lubrication and cooling with temperature monitoring are provided by a specially developed process in which an oil-containing aerosol flows through the bearing and gearbox for optimum supply. The one-piece machine bed of the Hi-TECH 750, made of Meehanite cast iron, absorbs vibrations excellently and, even in the smallest version with a turning length of 2 m, weighs an impressive 22 tons. Available with Siemens and Fanuc controls and numerous equipment options, it is predestined for large workpieces and demanding alloys.

New automation solutions for machining centers

The parent plant in Gwangju, Korea, was also able to convince with two new series of cost-effective automation solutions for milling machines.

The new HMP series is an automation solution for machining centers that allows the fully automatic loading and unloading of pallets with standard market formats up to a weight of 2 tons. The pallet pool, which is arranged in a rack design and the number of which can be individually adapted according to capacity requirements, enables the automation of one or two machines at the same time. For smaller workpiece sizes up to 300 mm in diameter and 80 kg in weight, the AWC series (Automatic Workpiece Changer) is now available and is built in two sizes with 8 or 20 magazine positions. Loading takes place laterally via a linear robot through an automatically opening bulkhead. HSK-T100 holders are used as workpiece holders. The workpieces are clamped onto these by means of vices, screw connections or other clamping systems. Loading and unloading by hand or crane takes place at the front-accessible setup station. Both innovations are available for almost all machining centers and even older machines can be retrofitted with them.

For more information, please visit: https://www.hwacheon-europe.com/en/blog

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech