Navigation : EXPO21XX News » Metalworking » KAPP NILES has developed an automatic tool change system

KAPP NILES has developed an automatic tool change system

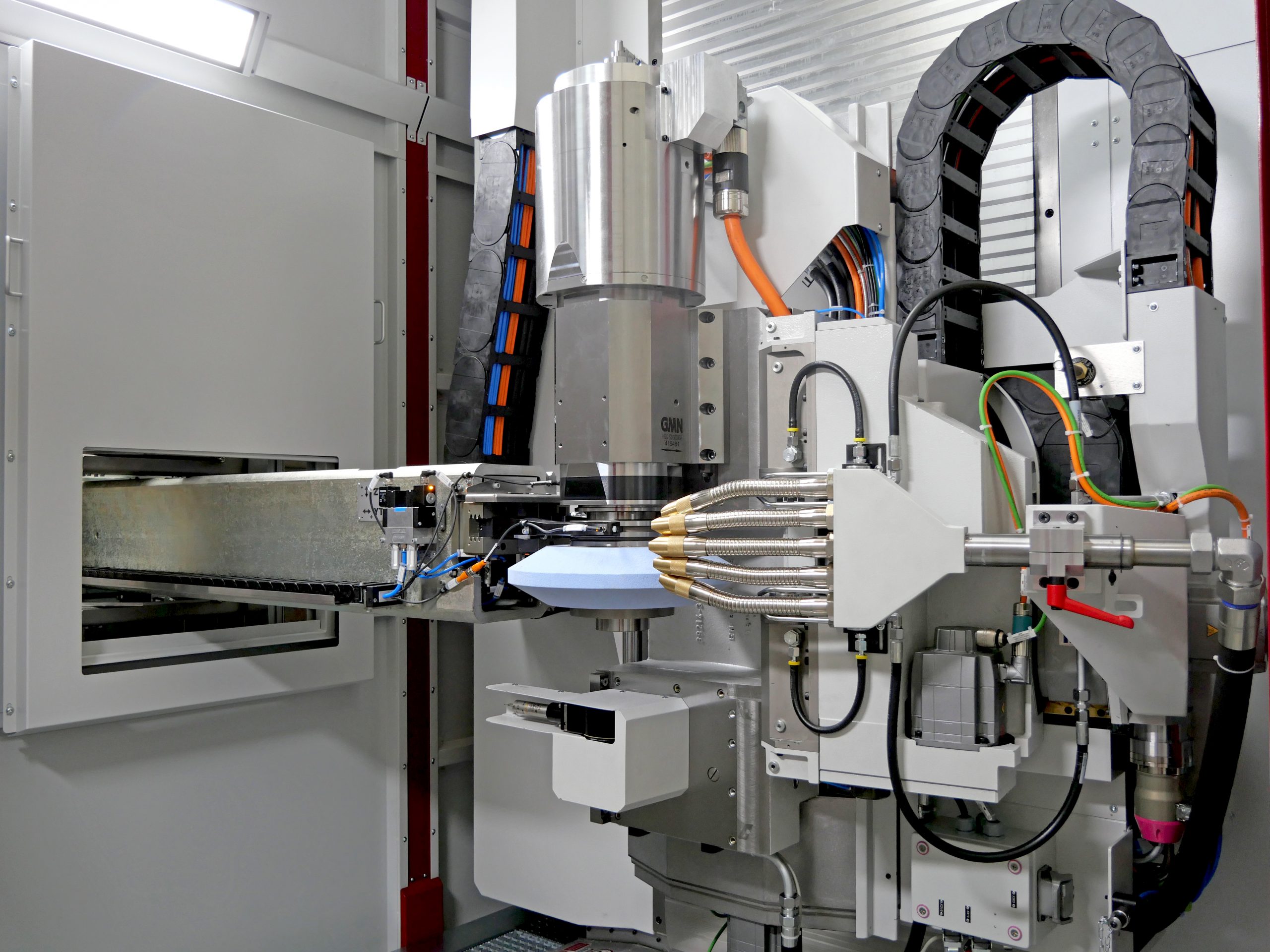

When manufacturing large gears, e.g. for wind power gearboxes, the demands regarding surface quality of the ground tooth flanks are increasing. At the same time, ever shorter grinding and set-up times are required to increase cost efficiency. To combine maximum productivity with the highest machining quality, we have developed an automatic tool change system. This allows the use of multiple grinding tools for different grinding operations – with a changeover time of less than two minutes.

Advantages

- Complete tool change including spin cycle < 2 minutes

- Surface roughness Ra < 0.2 µm achievable through the use of fine grinding wheels

- Qʹw ≥ 30 mm3/(mm.s) achievable in the roughing process through the use of high-performance roughing wheels

- Fewer dressing cycles thanks to reproducible grinding wheel positioning

- Ergonomic set-up outside the machine parallel to primary processing time

For more information visit: kapp-niles.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech

Related Expos

Tags

automation

digital cameras

drive system

factory automation

handling technology

industrial automation

industrial camera

industrial electronics

industrial robots

industrial sensor

industrial vision

Industry 4.0

intralogistic

intralogistics

laser applications

machine tool

machine vision

manufacturing process

materialhandling

material handling

measurement sensor

measurement systems

metalworking

motion control

motion drive

process industry

pumps

sensor technology

software

warehouse