Kern: Breakthrough in Ceramic Processing

With diligent research Kern Microtechnik GmbH succeeded in taking high-precision processing of technical ceramics to a new level. The basis is a unique ductile cutting mode on a modern Kern machining center with special tools from 6C Tools. Of course, the new process will be implemented in Kern’s machine shop.

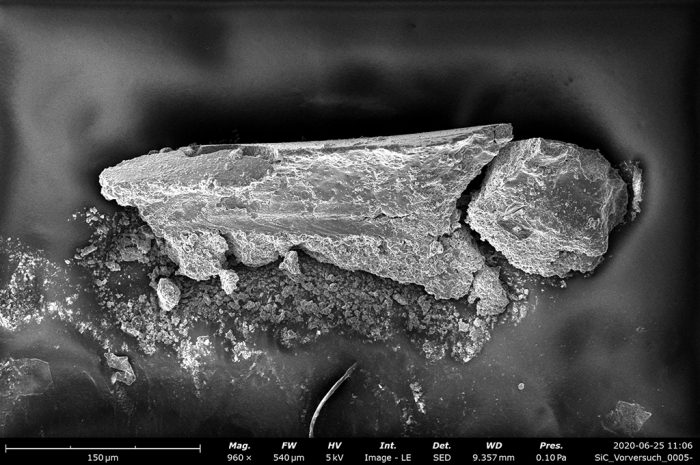

There are many advantages of technical ceramics, for example silicon carbide and aluminum oxide among others. The material is very hard, very stiff, resistant to chemicals and heat and conducts temperatures. The only disadvantage is a brittleness which makes many efficient application processes impossible. According to Kern’s project manager, Marvin Gröb, the main reason why ceramics are not used more often is the expensive finishing. The finishing adds up to 80% of the whole part.

It was the goal for Marvin Gröb and his team to bring the cost down and provide a reliable process. The engineer confirms: „Our research paid off. Together with the tool experts from 6C Tools we were able to develop a ductile cutting mode. When ceramic is being milled it no longer breaks but you can see chips flying instead.”

Tests confirm that this combination sets a new standard in the industry for material removal rates. At the same time, this process also reliably eliminates chipping of the edges and extends tool life.

„In addition, we can also drill holes that are significantly deeper than before, and with our Kern Micro series we can achieve the highest surface quality, accurate down to the µm”, explains developer Marvin Gröb.

The revolutionary development is of course relevant for Kern’s machine shop. The project manager is in close contact with the shop manager to bring the benefit of this groundbreaking process to Kern’s shop. Together they are working on implementing the new cutting mode in projects with ceramic components – prototyping, serial and single part production all benefit from the phenomenal process. Another great success for Kern.

For more information, please visit: https://www.kern-microtechnik.com/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech