KONFEKT – Experience ultra-thin glass on roll for flexible electronics at LOPEC by SCHOTT

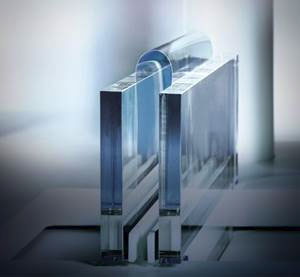

SCHOTT’s ultra-thin glass is produced environmentally friendly at the plant in Grünenplan, Germany. Thanks to the SCHOTT down draw process for direct hot forming, the molten glass is pulled through a nozzle in the desired thickness levels. Photo by SCHOTT AG

With support from the German Federal Ministry of Education and Research (BMBF), technology development partners Fraunhofer Institute for Organic Electronics,Electron Beam and Plasma Technology FEP, SCHOTT AG, VON ARDENNE GmbH and tesa SE have been developing new applications for ultra-thin glass on roll since 2013 in the research consortium KONFEKT

The partners are planning to introduce the first results together at an international technology and networking event, VISION | Flexible Glass, April 4-5, at Fraunhofer FEP in Dresden, Germany.

Glass which is bendable and flexible enough that it can be transferred directly from the melt to the roller for wrapping is not something out of a science fiction film, but rather a real product for the here and now. At the leading international exhibition for printed electronics, LOPEC, March 28-30 in Munich, each of the partners will have flexible thin glass on display at their respective exhibition booths. The international technology group SCHOTT is presenting different types of ultra-thin glass from its portfolio, which, due to their measure of flexibility, can not only be wrapped around a finger, but also onto rolls. The highlight at the company booth is a close-to-production prototype of ultra-thin glass on roll, which is currently being further developed and optimized through mid-2018 under the auspices of the research project KONFEKT in close cooperation with the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (Fraunhofer FEP), the specialty adhesive tape producer tesa SE and German equipment manufacturer VON ARDENNE GmbH.

Ultra-thin glass as basis technology

With a minimal thickness of 25 micrometers (µm) SCHOTT’s innovative ultra-thin glass is thinner than a single human hair. In ultra-thin thicknesses of less than 150 micrometers this glass has proven to be bendable yet stable. This leads to advantages over other substrate materials such as plastics, metals or silicon. In addition, as an inorganic material, glass offers a wide variety of benefits, whether it is in terms of optical quality, temperature stability, chemical consistency, gas density or mechanical resistance.

Ultra-Thin Glass for the Optoelectronics and Semiconductor Industry

https://www.youtube.com/watch?v=4iEh5BitUAs

VISION | Flexible Glass

Since the fall of 2013 the partners have been working together to drive forward the development of a “convertible thin-glass functional substrate for applications in organic electronics”. The KONFEKT project is planned to run until mid-2018, but it has already produced significant results. Since the previous year, for example, the team was able to significantly enhance the glass edge strength. Despite the fact that there are still more challenges to manage and overcome in the next several months, the development partners are optimistic that through intensive research work and very close and productive collaboration, they will be able to bring glass on roll to market readiness together.

“Printed electronics is an interesting growth market where ultra-thin special glass can represent the optimal substrate for it,” notes Thomas Wiegel, application engineer for ultra-thin glass at SCHOTT, adding, “which is why we are looking forward to giving visitors at LOPEC and VISION | Flexible Glass an exclusive preview of our research results thus far. We plan to have a close-to-production prototype of glass on roll with us, which tangibly demonstrates where we are at the moment and in which direction we are planning to go forward with it.”

Target: Avoiding glass breakage

Because it is absolutely critical to avoid any breakage of the ultra-thin glass when rolling or processing it, the consortium partners are currently placing their focus on the optimization of this aspect of their combined research. Ultimately, the goal is to deliver a glass on roll which meets the highest possible quality standards.

Each partner participating in the KONFEKT project brings its unique expertise to the research consortium with the aim of achieving a robust and unbreakable glass on roll by the end of the project, which maintains its functional surface area through coating and laminating processes. SCHOTT provides its expertise in ultra-thin glass along with its deep knowledge in the processing and chemical optimization of glass. tesa SE, with a long history of providing adhesive tapes on rolls, gives the glass its finish by laminating it with specialty adhesives and functional layers.

“As an innovative mechanical engineering company, VON ARDENNE brings decades of experience in the development and manufacture of roll-to-roll coating machinery for films and metal strips to this project, not to mention a wealth of know-how in magnetron sputtering for large-scale glass coating,” explains Dr. Andreas Nilsson, Vice President Web Coating for the Dresden-based company. “With our new web coating system, the FOSA LabX 330 Glass, we want to demonstrate today the feasibility of this forward-looking technology and we are truly thrilled about the exciting application development made possible based on flexible glass,” added Nilsson. VON ARDENNE will also be at LOPEC presenting its latest solution. The new system is scheduled to make its live debut to an audience of industry professionals when it is introduced at the VISION | Flexible Glass workshop.

For more information visit: http://www.schott.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech