Lidering: The new mechanical seal LMS23 for agitators

Recently Lidering has incorporated to its catalogue a new LMS23 seal, designed and produced by its industrial engineers from the custom manufacturing section.

The passion is among Lidering’s corporate values. Lidering is passionate about what they do and therefore they are constantly improving and innovating their services and products.

Part of this passion and innovation make Lidering to investigate new solutions that add value to anything they offer their clients.

This desire for continuous improvement and Lidering’s expertise as leaders in sealing solutions create an ideal scenario to achieve their goal.

For this reason, in this article they will detail one of their latest designs that they have added to their catalog.

If you want to know the characteristics of the new LMS23 seal and the properties that make it an ideal solution for top agitators, please read on.

Particularities in the sealing of sensitive industries

Before going deeper into the LMS23 seal, we will see some particularities about sealing in sensitive industries.

In sensitive industries such as pharmaceutical or food, there are specific challenges in mechanical seal design and system selection.

These challenges continue to evolve as new processes are developed. Although there are differences between these industries, there are also many similarities.

There is no mechanical seal design that is suitable for all applications. Specific material selection and design features must be thoroughly examined for each application.

Fortunately, there is a broad experience with the applications in these industries and it provides Lidering with guidance for sealing in the most of applications.

However, as with any application, successful sealing can only occur if process conditions, state of the equipment, and cleaning/sterilization requirements are perfectly known.

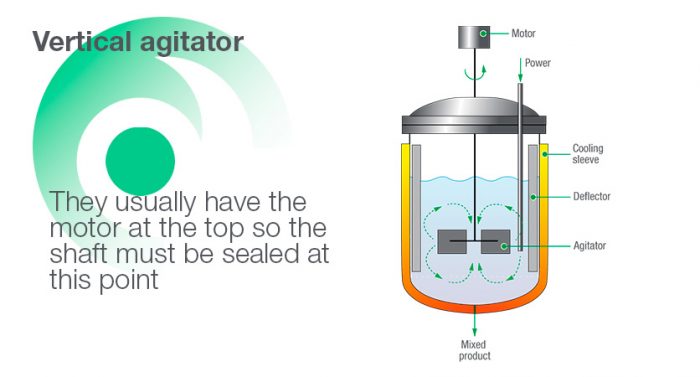

Vertical agitators and mixers

An industrial agitator can be defined as any bulk processing equipment designed to mix or blend heterogeneous materials to form a homogeneous final product.

Mixers and agitators are present in around the world and are often used to mix foods, chemicals, pharmaceuticals, household products, plastics, and minerals.

Vertical agitators are a type of machinery with a spiral mixing tool that creates an upward flow of unmixed products at the periphery, as well as a downward flow of mixed products around the shaft.

Vertical agitators usually have the motor at the top so the shaft must be sealed at this point.

This presents an important feature of the application. The fluid, which is at the bottom of the agitator, does not normally come into contact with the seal, therefore the seal cannot depend on the product fluid to guarantee its lubrication.

This characteristic means that the seal must be prepared to work dry without lubrication.

In addition, in this type of processes, although the working pressures are not very high, it is common to create a vacuum inside the agitator.

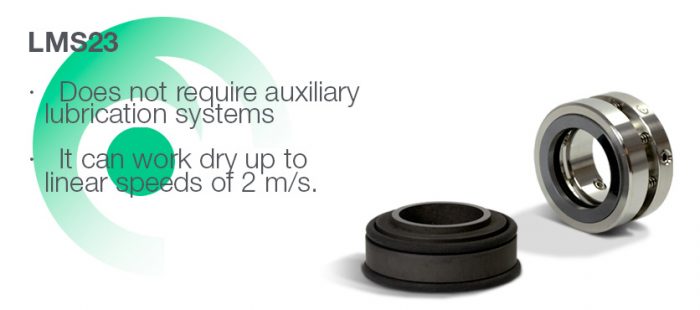

LMS23 mechanical seal

The new LMS23 mechanical seal brings together different characteristics that make it a suitable solution for top agitators.

As mentioned before, Lidering can use it without applying any auxiliary lubrication systems.

Thanks to the self-lubricating properties of the special graphite on one of its friction faces, LMS23 can work dry up to linear speeds of 2 m/s.

It also complies with the certifications that are usually required by sensitive industries such as the FDA, the CE or even ATEX.

If you want to consult the certifications with which Lidering can supply their mechanical seals, visit Lidering’s web page with certificates.

Another strong point of this mechanical seal is its balance. The special design of its friction faces allows it to withstand vacuum environments in the range up to 10 bar.

Other characteristics:

- Fixation system to the shaft through Allen screws.

- Independent direction of rotation.

- External mounting.

Components of its design:

- Rotating friction face.

- Fixed friction face.

- 3 O-rings.

- Spring.

- Metal casing.

- Fixing screw.

For more information, please visit: https://www.lidering.com/en/blog/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech