Lödige: MIXTURE OF BOUILLON MASS AS A TECHNICAL PROCESSING TASK

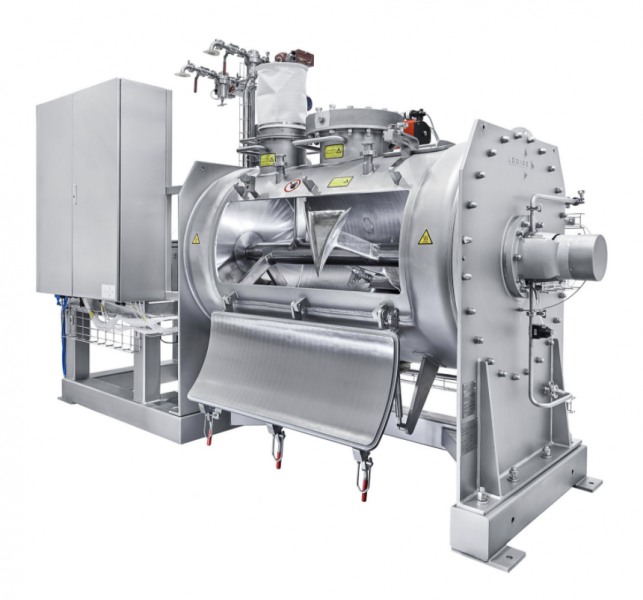

Instant soups and bouillon cubes are a convenient and fast snack, but the production demands complex process technology requirements. Not only are the ingredients numerous but also extremely different in terms of consistency and composition. An effective opportunity to implement this demanding mixing task provides the Lödige Ploughshare® Mixer type FKM.

From dry powder to sticky and partly liquid products: The ingredient list of bouillon mass such as soft and hard bouillon includes components of nearly every consistency. For various products, powder with a large amount of salt and sugar, colouring substances, flavour oils, spices, melted fats like palm and chicken fat as well as additional liquids need to be processed into a mixture that is as homogeneous as possible. This task is especially demanding due to the different solubility of the recipe ingredients in fat and water. Besides that, a defined swelling of dry starch components must be ensured during the wettening phases. And last but not least, instant soups and bouillon cube mixtures are about the perfect pouring and dosing properties of the product.

The challenge: The desired characteristics for every recipe and every batch must be produced quickly, precisely, and reproducibly within the shortest time possible. The process and the machine must of course meet all food technology and hygiene demands.

Ploughshare® Mixer type FKM for batch production

Using the horizontal Lödige Ploughshare® Mixer type FKM, these complex technical process requirements can be met. The mixer is preferably used for batch production. Depending on the production quantity and application, the model sizes available are designed for 300 litres for small batches and up to 8,000 litres for large-scale production. The mixer works according to the mixing and fluidisiation process developed by Lödige. Special mixing tools that are systematically arranged on a shaft produce a three-dimensional mixed goods movement, a so called mechanically generated fluid bed. Due to this intensive and, if needed, at the same time gentle product movement, solid or liquid small and micro components can be distributed extremly fast and homogeneously in a batch.

Lödige offers various liquid addition possibilities as needed. The respective optimal solution is designed according to the specific needs of the application and recipe. The amount of liquid can be between 1% and 30%. At the same time, the mixer meets all requirements of “hygienic design”, which food manufacturers require as part of their plant planning. Lödige is a member of the European Hygienic Engineering & Design Group (EHEDG) and develops innovative concepts for mixing systems corresponding with these guidelines. Essentially the Ploughshare® Mixers features are: an easy to clean design, manufactured entirely of stainless steel, surfaces in contact with product are at least Ra < 0.8 µm, a completely welded mixing unit with optimised shovel clearance from the wall, air-purged low-maintenance shaft seals, large inspection/cleaning openings, enlarged discharge opening(s) for minimised remaining material, drives and bearings featuring stainless steel covers, and where required a (partially) automated wet cleaning (Washing in Place WIP/Cleaning in Place CIP).

For more information, please visit: https://www.loedige.de/loedige/presse/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech