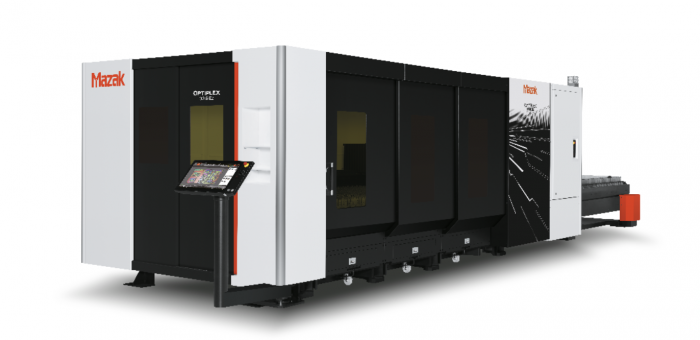

Mazak introduces the OPTIPLEX Ez series: Precision laser cutting made easy.

Photo by Yamazaki Mazak

Yamazaki Mazak, a global leader in cutting machine tools and advanced manufacturing solutions, is excited to introduce its latest innovation in 2D laser cutting technology—the OPTIPLEX Ez machine series. This new series includes two entry-level models: the OPTIPLEX 3015 Ez and the OPTIPLEX 4220 Ez. Both machines offer users high ease of operation and outstanding performance at an affordable price.

Easy to Use and Maintain

The OPTIPLEX Ez series seamlessly combines exceptional cutting performance with simple maintenance, taking fiber laser cutting to a new level. These machines are designed for efficient cutting processes and are equipped with high mechanical rigidity, remarkable precision, and unparalleled reliability. Intelligent features provide users with highly efficient assistance and protective measures, minimizing setup times and optimizing productivity.

The OPTIPLEX Ez is the ideal machine for those seeking a straightforward entry into laser cutting. The Mazak Ez series offers simplified functions in conjunction with an integrated cutting database, making it suitable for first-time users of laser cutting technology and providing a cost-effective and economical solution.

Standard features include the new cutting head with autofocus and the new fiber laser resonator, both designed to quickly adapt the machine to the materials being cut. The unique design of the cutting head facilitates fast, uncomplicated, and economical maintenance, as the protective glass and lens can be easily replaced on-site without needing a specialist. This is made possible by a specific cover that prevents contamination during the exchange.

The OPTIPLEX Ez machines operate with a fiber laser source, ensuring low power consumption and streamlined maintenance while eliminating the need for laser gas. Available in 3 kW, 4 kW, and 6 kW power variants, the OPTIPLEX Ez machines are suitable for various machining applications and can be easily integrated into automated manufacturing systems to enhance operational efficiency.

Space-Saving Design and Innovative Control Technology

Large sliding doors at the front and side save space and make loading and unloading the machine a breeze. The rotatable and adjustable control unit of the CNC system allows operators to work flexibly from a position in front of or beside the machine. The robust cast iron construction guarantees high stability and accuracy, offering optimal protection against deformation.

The Mazak OPTIPLEX Ez machines are equipped with the new MAZATROL SmoothLx CNC control with a 21.5-inch screen and user-friendly interface. They are intuitive to operate and easy for less experienced operators to use.

OPTIPLEX 4220 Ez: Expanded Capabilities

With its impressively large working area of 2050×4120 mm, the OPTIPLEX 4220 Ez is aimed at users looking to process materials longer than 4 meters. This model stands out for its high flexibility and opens up new possibilities for various applications.

Both machine models, the OPTIPLEX 3015 Ez and OPTIPLEX 4220 Ez, are the best proof of how committed Mazak is to reliable, efficient, and accessible laser cutting solutions.

The model 3015 Ez is permanently displayed in Milan at Mazak’s European technology center for laser cutting technology, where Mazak customers have the opportunity to see live machining demonstrations showcasing the quality and advantages of this machine.

The OPTIPLEX 3015 Ez will also be exhibited at EuroBLECH 2024, where it will be showcased on the Mazak booth alongside a new automation system.

For more information, please visit: www.mazakeu.de.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech