NETZSCH’s PERIPRO peristaltic pumps offers energy-efficient and maintenance-free operation

Photo by NETZSCH Pumps

How does a peristaltic pump work? Netzsch will show the function of the peristaltic pump and how users benefit from using it. In addition to the already proven technologies of the NEMO® progressing cavity pump, the TORNADO® rotary lobe pump and the NOTOS® multi screw pump, NETZSCH now also offers PERIPRO peristaltic pumps.

Like all other pumps from NETZSCH, the peristaltic pumps also belong to the group of rotating positive displacement pumps and function according to this principle.

Important components for the peristaltic pump function

The special feature of the PERIPRO peristaltic pump is that it has only one wearing part, the hose. This means that only a minimum of maintenance is required. Four components are elementary for the function of the peristaltic pump:

- Hose

- Housing

- Bearing

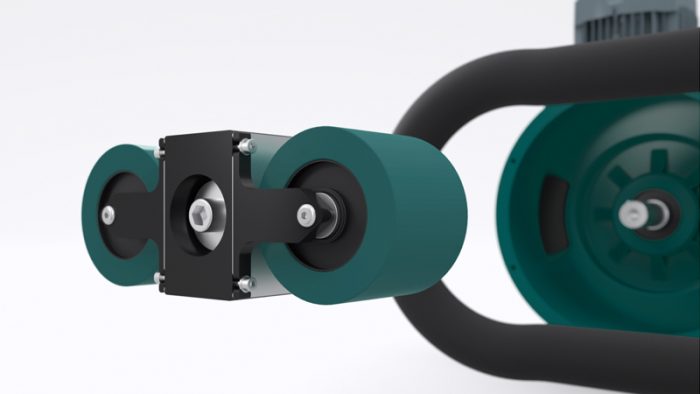

- Rollers

The hose is an exceptionally high-quality product produced by a unique manufacturing process. It consists of an extruded inner layer, a high-density textile reinforcement and a precision-manufactured outer layer. This ensures optimal compression. Users also benefit from its simple and quick installation, saving time and money. The hose materials are compatible with all types of products and working conditions, ensuring the smooth operation of the peristaltic pump. For the food sector, NETZSCH also offers users an FDA-certified version. The innovative housing design of the pump simplifies installation, commissioning and maintenance for users simultaneously. In addition to simple hose replacement, the maintenance-free PERIPRO peristaltic pump also consumes up to 90 percent less lubricant than conventional pumps. This is a decisive factor, especially with constantly rising oil prices. To offer maximum safety despite pumping aggressive, abrasive media with a high solids content, the PERIPRO is manufactured with oversized bearings and robust construction materials. This means that nothing stands in the way of safe and reliable conveying. NETZSCH relies on XXL rollers for the rollers, which minimises the starting torque and significantly increases the hose service life.

Peristaltic pump function

External mechanical deformation forces the medium to be pumped through the hose. The pump housing supports the hose and is clamped by the XXL rollers. The rollers rotate on a rotor. The rotation causes the pinch-off point to move along the hose, thus propelling the pumped medium. The elasticity of the hose material creates the suction vacuum and thus ensures the function of the peristaltic pump. Another advantage resulting from the design is the insensitivity to dry running. Using a peristaltic pump, users can convey even inconstant quantities or products with a high solids content without any problems.

Energy saving through functioning peristaltic pump

Photo by NETZSCH Pumps

The innovative design of the PERIPRO not only offers the maintenance-free operation of the peristaltic pumps but also enables users to save up to 30 percent energy. The XXL rollers ensure optimum compression of the hose without friction. This provides easy operation with minimal starting torque and an extensive frequency range. In addition to the energy savings, the service life of the hose is also extended, which minimises maintenance costs.

Peristaltic pump: Function and powerful delivery

PERIPRO peristaltic pumps are particularly robust due to their design, XXL rollers and oversized bearings. Furthermore, the peristaltic pumps have an extremely high suction capacity. In addition to reversible and powerful delivery, the PERIPRO also offers users the highest dosing accuracy with a deviation of less than one percent. This means users can dose with maximum precision even in applications with variable pressure. Thanks to the peristaltic pump function, nothing stands in the way of precise and powerful delivery.

Peristaltic pump function: One technology – three versions

As a global specialist in complex fluid management, NETZSCH offers users three different designs of peristaltic pumps to cover the broadest possible range of applications:

- PERIPRO hose pump in industrial version

- PERIPRO hose pump in food version

- PERIPRO hose pump in chemical version

Photo by NETZSCH Pumps

Whether for industrial, food or chemical applications, the PERIPRO hose pump functions according to the same principle and impresses its robustness and minimal maintenance requirements. Benefit from the function of the peristaltic pumps in the future and reduce energy requirements.

For more information, please visit pumps-systems.netzsch.com/.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech