New Nanoparticle Coating for Plasticating Screws by Nordson

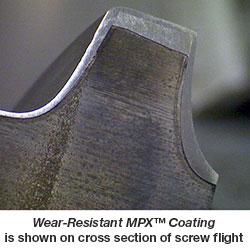

Photo by Nordson Corporation

Nordson’s Xaloy® MPX™ Technology for Single and Twin Screws provides improved Abrasion and Corrosion Resistance, with 61% less Mass Loss in Abrasion Tests

A technology that uses exceedingly tiny tungsten carbide spheres barely larger than the particles in cigarette smoke has yielded a coating for single and twin plasticating screws that resists abrasive and corrosive wear better than standard coatings applied by high-velocity oxygen fuel (HVOF) thermal spray.

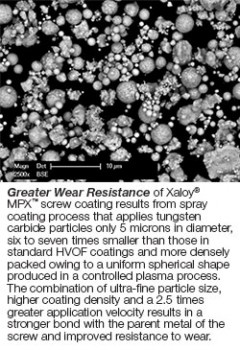

The new Xaloy® MPX™ thermal spray coating from Nordson is made up of particles only 5 microns in diameter. Consisting primarily of tungsten carbide, the particles are six to seven times smaller than those in standard HVOF coatings and more densely packed owing to a uniform spherical shape produced in a controlled plasma process. The combination of ultra-fine particle size, higher coating density, and a 2.5 times greater application velocity results in a stronger bond with the parent metal of the screw and improved resistance to wear.

Compared with standard HVOF tungsten carbide coatings, the Xaloy MPX technology exhibits 61% less mass loss in ASTM G65 abrasion testing, 18% less mass loss in ASTM G77 sliding wear testing, and 8.5% greater bond strength in ASTM C633 bond testing. As an example of corrosion resistance, the Xaloy MPX coating survived more than 1,000 hours of salt fog testing, in part because of its near-zero porosity.

Photo by Nordson Corporation

“Nordson’s Xaloy MPX screw coating provides best-in-class wear protection compared with standard HVOF coatings, and its higher bond strength eliminates potential for chipping,” said Mark Colella, global product manager for the Xaloy brand. “This new technology extends the working life of screws in extrusion and injection molding, enabling processors to work with some of today’s most challenging materials.”

Nordson recommends the Xaloy MPX technology for resisting abrasion from compounds with medium (15 to 35%) filler loadings and for resisting

corrosion from halogenated materials, including flame retardants and PVC. For filler content above 35%, Nordson supplies the high-hardness coating Xaloy® X-8000™.

New Xaloy MPX technology can be employed across the full range of screw diameters and may be applied to the entire screw or to specific areas. Standard layer thickness is 300 microns, with variations depending on the area of the screw. The MPX screw coating should be used with a barrel lined with Nordson’s Xaloy® X-800® nickel / tungsten carbide alloy or a comparable inlay.

Xaloy MPX technology expands Nordson’s offering of screw encapsulations for high-wear applications. The Xaloy® X-8000™ coating is a nickel-based alloy with high tungsten carbide content that is first applied in an HVOF process, then fused to the parent metal of the screw to form a metallurgical bond.

For more information visit: http://www.nordson.com/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech