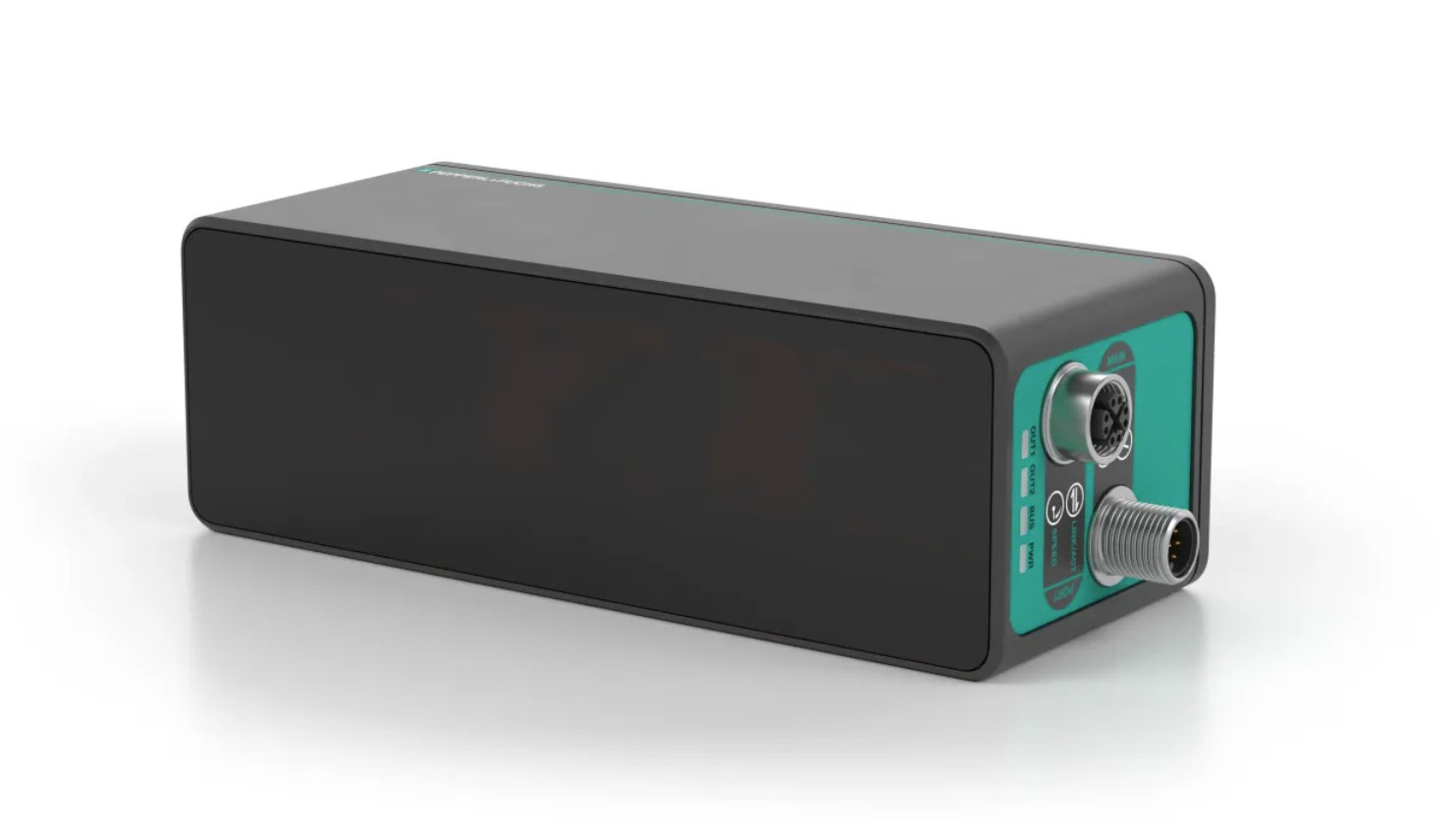

Precise 3-D Measurements with the SmartRunner Measurer 3-D

The SmartRunner Measurer 3-D with integrated data processing sets new standards in industrial 3-D measurement technology. Using stereo vision technology, volume, dimensions, rotation, and position are calculated directly in the device—without any external image processing. Even at object speeds of up to 2.5 m/s, the intelligent vision sensor delivers precise results. Find out more about the high measuring accuracy, convenient setup, and versatile application possibilities of the new 3-D vision sensor from Pepperl+Fuchs.

Precise Measurement Results for Static and Dynamic Applications

The new SmartRunner Measurer 3-D vision sensor captures the complete 3-D information of objects with just a single shot and calculates all relevant measured values for shape, position, and orientation directly in the device.

The basis for this precise object measurement is stereo vision technology. Two offset cameras capture the scene simultaneously from different perspectives. Based on the disparity between the two images, the SmartRunner Measurer 3-D uses triangulation to calculate the exact depth information and generates a complete 3-D image of the object—for both static and dynamic applications at object speeds of up to 2.5 m/s.

An integrated projector additionally casts a fine structured pattern on the object’s surface, providing stable reference points even on challenging materials. This allows the vision sensor to achieve high depth precision and repeat accuracy, regardless of color, surface, or material.

Flexible Integration and Simple Operation via ViSolution Software

The SmartRunner Measurer 3-D can be easily integrated into a wide range of automation environments and delivers precise measurement results directly to the PLC via Modbus TCP. Alternatively, an Ethernet TCP/IP interface is available, which can also be used to provide image data for documentation and analysis purposes. Thanks to optional gateways, the sensor can be easily integrated into PROFINET, EtherNet/IP or EtherCAT networks. This gives users maximum flexibility for their system structure.

The 3-D vision sensor is set up and operated using the user-friendly ViSolution software. With its clearly structured user interface, live images, and preconfigured functions, the sensor can be put into operation in just a few steps. Individually customized parameters such as exposure time or Region of Interest (ROI) ensure that the sensor can be perfectly adapted to any application. Measurement results and image data can be visualized and checked immediately and without special image processing knowledge. The ViSolution software makes commissioning, parameterization, and analysis a breeze.

For further information visit: https://www.pepperl-fuchs.com/en/news/precise-3-d-measurements-with-the-smartrunner-measurer-3-d-gn8512

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech