Rack and spiral drive for stack molds by Knarr

Increased efficiency through stack molds

Double the output with the same tool and machine size, manageable investments and significantly lower unit costs? To make sure that this idea does not remain an illusion, some injection molders rely on stack molds, especially for flatter plastic parts.

In contrast to the classic injection mold, two or more parting lines are located parallel one behind the other. This arrangement is one of the most important arguments for stack molds: The clamping force of the machine is used optimally.

A doubling of the cavities means a doubling of part production. The proportionately calculated machine hourly rate is distributed over the significantly higher production quantity, thus leading to significantly lower unit costs and an enormous increase in productivity.

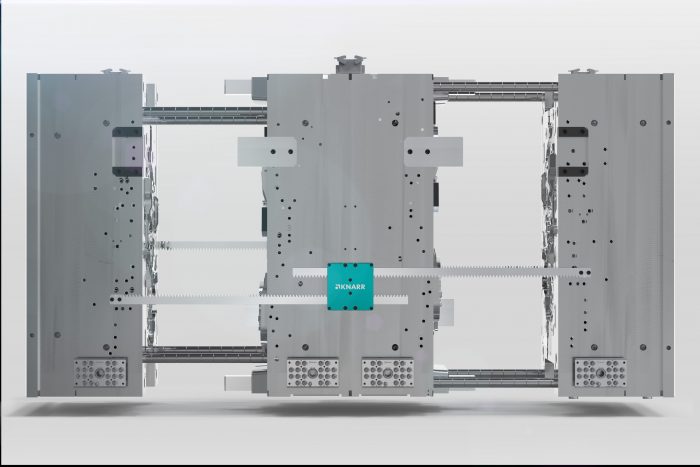

In the classic design, a stack mold consists of a central central part and two ejector sides. KNARR now offers two different drive mechanisms for synchronous stroke movements on both sides. Both alternatives can be flexibly adapted to the required length according to your requirements.

Rack and pinion gear (Art.No. 461000)

The classic rack and pinion drive, which can be quickly and easily mounted on the tool as a pre-assembled unit. Two or four of these drives are installed on the mold, depending on the mold size. A closed housing provides additional stability. The well-known but optimized design offers more than 30% space savings compared to related drives.

Spiral gear (Art.No. 462000)

The innovative solution in the area of floor drives: A special spindle geometry enables significantly higher load transmissions. At the same time, the even more compact design reduces the space required at the mold to a minimum. The use of handling robots or an additional injection unit therefore presents no difficulty. The spiral drive is a worthwhile option not only for high-speed moulds.

For more information, please visit: https://knarr.com/company/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech