Renishaw to demonstrate its manufacturing solutions at MACH 2016

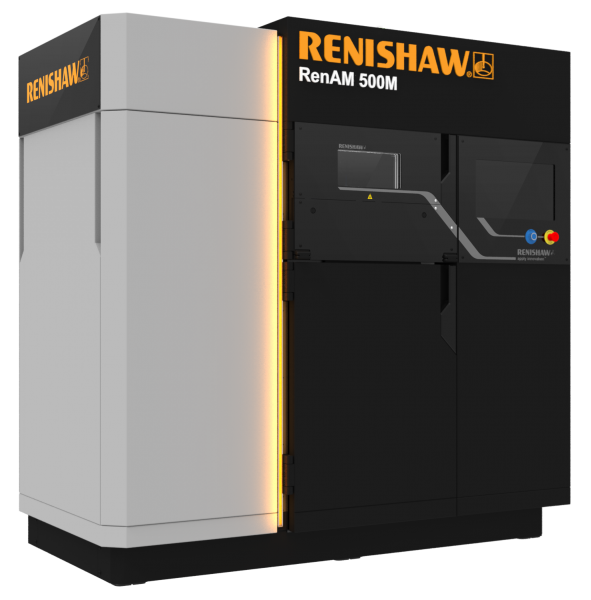

RenAM 500M

Photo by Renishaw plc

Renishaw, a world leader in precision engineering technologies, will be exhibiting its extensive range of metrology and additive manufacturing equipment at MACH 2016 which takes place at the NEC, Birmingham, from 11th to 15th April. Renishaw will be exhibiting on stand 5730, Hall 5, showing its new RenAM 500M additive manufacturing system, as well as its new non-contact vision measurement probe system (RVP) for CMMs. Also demonstrated will be new software for the Equator™ flexible gauge which allows users to create simple gauging routines in minutes, the new MODUS 2™ metrology software suite which simplifies the programming of co-ordinate measuring machines (CMMs), plus Renishaw’s full suite of machine tool probes, calibration products, metrology fixtures, styli and position encoders, including the Queen’s Award-winning Resolute™ absolute encoder.

Making its UK trade show debut will be the RenAM 500M. Fully designed and engineered in-house to be used for serialised production, the RenAM 500M builds complex metal components directly from CAD using metal powder fusion technology. Highlights of the system include a Renishaw designed and engineered optical system with dynamic focussing, automated powder sieving and recirculation, a 500 W ytterbium fibre laser and patented high capacity dual filter SafeChange™ system.

MACH also sees the UK trade show launch of Renishaw’s new vision measurement probe (RVP) for use with the REVO-2 5-axis measurement system on co-ordinate measuring machines (CMMs). RVP increases the multi-sensor capability of REVO-2 by adding non-contact inspection to the existing touch-trigger, high-speed tactile scanning and surface finish measurement capability of the system.

For certain applications, non-contact inspection provides clear advantages over traditional tactile probing techniques. Thin sheet metal parts, components with large numbers of holes (as small as 0.5 mm), and parts which are not suited to tactile measurement can now be fully inspected with the RVP system. This new innovation also gives exceptional improvements in throughput and CMM capability by utilising the 5-axis motion and infinite positioning provided by the REVO head.

At MACH 2016 Renishaw will also, for the first time in the UK, demonstrate its new INTUO™ gauging software which is now offered with the unique Equator system to simplify and automate the gauging of a wide variety of parts. The software removes dependence on skilled operators and presents a cost-effective alternative to multiple manual devices such as vernier or digital callipers, micrometres and plug gauges.

Renishaw is also launching the Equator Button Interface (EBI), with simple push-button controls for shop-floor operators, removing the need for a mouse and keyboard. The EBI can be operated by staff wearing gloves and is not affected by shop-floor contamination.

Users of co-ordinate measuring machines visiting MACH 2016 will also be interested to see how the MODUS 2 metrology software suite brings new levels of clarity and efficiency to the programming and operation of CMMs. Based on the established and highly capable MODUS platform, and supporting Renishaw’s range of three and five-axis CMM sensor technologies, MODUS 2 has been designed with usability in mind, including an innovative, easy-to-learn interface and faster programming, resulting in unprecedented levels of productivity with or without a CAD model.

The user experience for MODUS 2 is also designed to be identical whether the software is connected to a ‘live’ CMM or working in an offline environment where full simulation with speed control allows measurement sequence development and visualisation. Further innovations include ‘Off Surface’ motion technology, intelligent measurement strategies, automatic reporting and an interactive virtual CMM environment. From simple manual machine operation through to complex part measurement on multi-axis systems, MODUS 2 adapts automatically and only offers functionality relevant to the current task.

Renishaw will also be exhibiting its game changing SPRINT system which brings exceptional, high-speed, high-accuracy scanning to CNC machine tools. SPRINT records a constant stream of accurate 3D points across the part surface, and analyses this data in real time on the CNC machine tool controller, to provide game-changing opportunities for automated in-process control.

Renishaw will also be demonstrating its new Linear diagonal measurement kit for its XL-80 laser measurement system. Laser diagonal tests can be used to measure diagonal positioning and reversal errors in accordance with B5.54 and ISO 230-6 standards. The ISO 230-6 standard states that diagonal displacement tests allow the estimation of the volumetric performance of a machine tool. The new kit is quick and easy to set-up, is easy to align and allows fast data analysis to international standards.

For more information, please visit http://www.renishaw.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech