Six Questions & Answers About Hose Pumps

Do you seek to decrease lubricant consumption and achieve energy savings? If so, hose pump technology is well-suited for your application. We’ve condensed essential information on hose pumps for your convenience.

Precise and controlled pumping of media with high solids content is crucial in industries where accurate dosing, gentle pumping, and contamination prevention are paramount. Hose pumps, also known as peristaltic pumps, are gaining popularity in this context. Learn everything you need to know about hose pumps here.

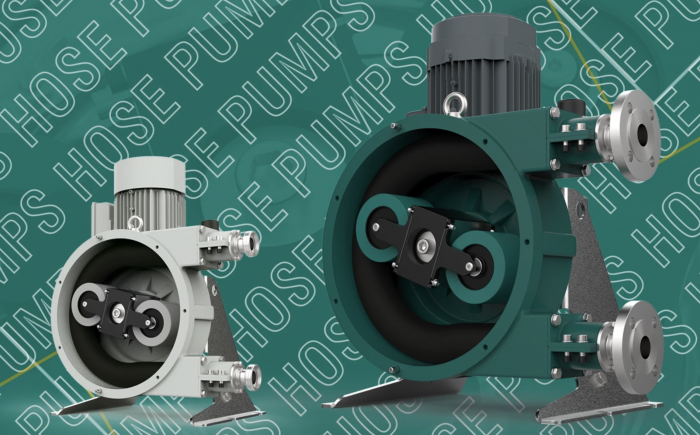

What are hose pumps?

Hose pumps, or peristaltic pumps, are positive displacement pumps utilized to pump liquids with a high solids content. The fundamental construction involves a flexible hose squeezed by a rotor or roller mechanism, facilitating the forward movement of liquid in the hose. These pumps find applications in various industries like chemicals, food processing, pharmaceuticals, and environmental technology, offering gentle conveying and precise dosing.

Photo by NETZSCH Pumpen & Systeme GmbH

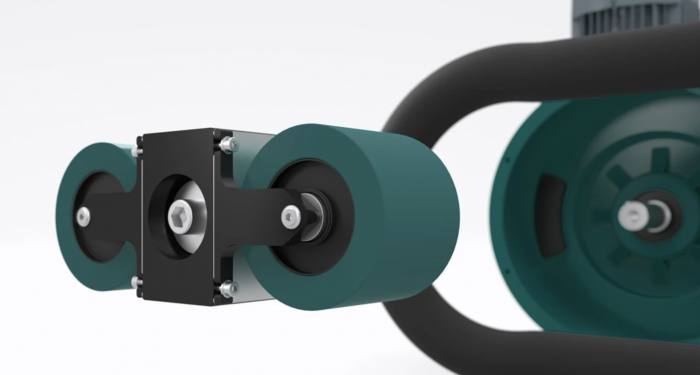

How is a hose pump constructed?

Hose pumps comprise key components:

- Flexible hose

- Rotor or roller mechanism

- Pump housing

- Drive system

- Inlet and outlet connections

The flexible hose, a central element, is compressed and then expands. The rotor or roller mechanism facilitates the periodic squeezing of the hose, ensuring liquid is pumped forward. The pump housing encloses these components, protecting them while allowing control of pressure and flow. A motor or drive system powers the rotating element, creating the squeezing movement. Inlet and outlet connections enable the introduction and discharge of the medium.

How do hose pumps work?

Hose pumps operate on the peristalsis principle, involving the periodic squeezing movement of a flexible hose by a rotor or roller mechanism. This action propels the liquid forward, creating pressure that moves the fluid towards the pump outlet. The relaxed hose then draws in liquid for the subsequent pumping cycle. This continuous process ensures even and minimally pulsating fluid pumping.

Photo by NETZSCH Pumpen & Systeme GmbH

What are hose pumps used for?

Hose pumps find applications in industries requiring precise and gentle pumping of liquids with high solids content. These include the chemical industry for safe and precise conveyance of various chemicals, food processing for ingredient dosing, pharmaceuticals for precise medicine dosing, and environmental sectors for robust handling of water sampling, chemical addition, and sludge and wastewater pumping.

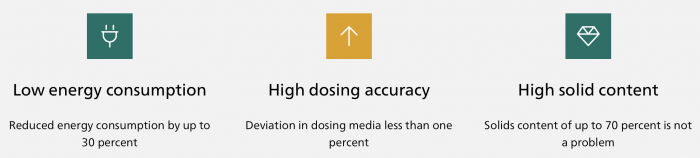

What are the advantages of hose pumps?

Hose pumps offer versatility and numerous advantages, such as gentle liquid pumping, self-priming capability, resistance to dry running, uniform and pulsation-free flow, and ease of maintenance with the hose being the only wearing part. They minimize the risk of contamination, leaks, and energy consumption while accommodating abrasive and aggressive media.

Where to buy hose pumps?

NETZSCH Pumps & Systems is a leading global supplier of hose pumps, offering the robust and maintenance-friendly PERIPRO® hose pumps suitable for aggressive and abrasive media with up to 70 percent solids content. With over 70 years of experience, NETZSCH provides Proven Excellence in pump performance.

If you’re unsure about the suitability of hose pump technology for your application, no worries! NETZSCH collaborates with you to find the right pump solution, offering a range of technologies tailored to handle complex media.

For more information, please visit: https://pumps-systems.netzsch.com/en/news

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech