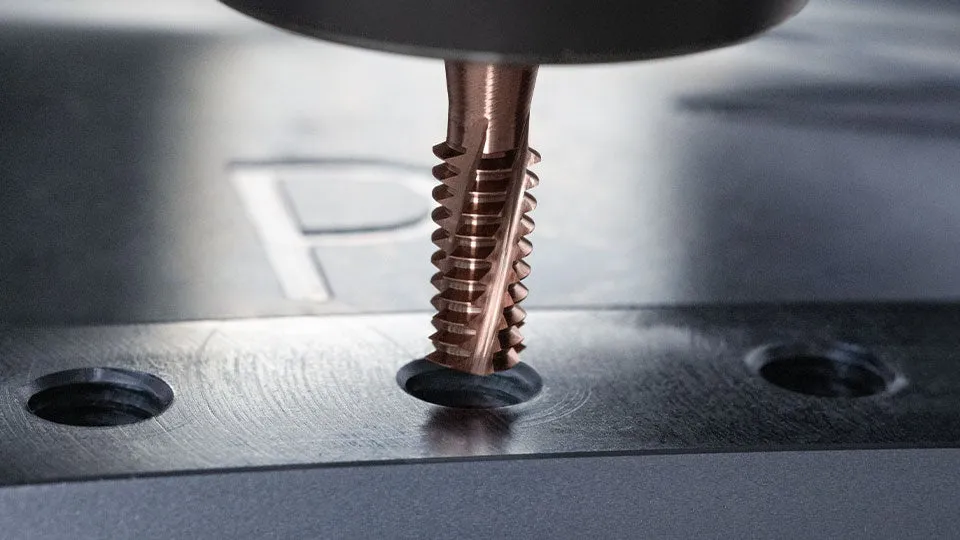

The Walter TD610 Supreme thread mill redefines the standard

With the TD610 Supreme, Walter AG presents a thread milling cutter family that sets new standards in terms of performance and process reliability. The successor to the proven TC610 Supreme not only significantly exceeds its performance and machining times in tests, but also those of the best competitors on the market to date. One of the reasons for this is the highly wear-resistant HiPIMS coating WB10TU made of AlTiSiN. It is extremely smooth, robust and wear resistant – and ensures a significantly longer service life compared to conventional coatings. In addition, the thread milling cutter has unique geometric features, such as the “trumpet bow neck”, a tapered neck and groove geometry that reduces deflection, prevents tool breakage and allows regrinding in case of wear.

Photo by WALTER

The offset distribution of the flutes minimizes vibrations, especially with short threads, thereby improving thread quality and process reliability. This also applies to the special post-treatment of the TD610 Supreme, these polished cutting edges reduce wear, increase stability and improve thread quality even in the most demanding materials – while also increasing cutting speeds and reducing machining time. The full-profile thread milling cutter is universally applicable for blind and through threads in all ISO material groups, P, M, K, N and S, up to 48 HRC. Radius corrections are rare thanks to the stable process, which makes the TD610 Supreme ideal for both short-run or high-volume “lights-out” production. Walter offers the thread milling cutter for thread depths up to 1.5 × D(N), with and without internal cooling, and in many common standards like: M, MF, UNC, UNF and G. It should be of particular interest to users with demanding requirements, such as those working with expensive components.

For more information visit:

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech