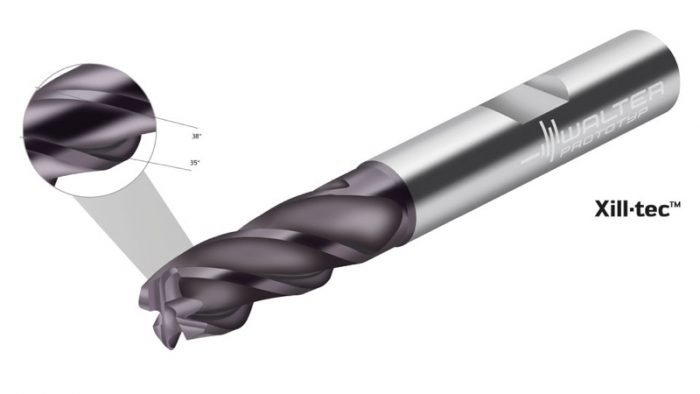

Walter expands its MC230 Advance range with the new Xill·tec™ solid carbide milling cutters

Photo by Walter Deutschland GmbH

With Xill·tec™, the solid carbide milling cutters in the MC230 Advance product range, Walter is presenting a new range of products: A new type of high-performance geometry with an asymmetrical helix (35°/38°) was combined with Walter’s own wear-resistant and high-performance grade WK40TF. The result is a tool family with high performance that also offers universal applicability for roughing and finishing. The milling cutter experts have consolidated the developments of the past ten years in the Xill·tec™ range. The asymmetrical helix, the most important feature of the geometry, enables smooth, low-vibration operation: This is essential for long tool life and process reliability. Fractures are avoided and the high level of operational smoothness contributes to the soft cutting action of the Xill·tec™ milling cutter.

The solid carbide milling cutters are suitable for all ISO material groups (P, M, K, N and S) as well as all common milling operations, such as shoulder milling, ramping, (helical) plunging and full slotting (up to 1×D), while exhibiting a high performance level. This is also true for innovative machining strategies such as dynamic milling. The comprehensive range of products also contributes to the universal applicability of the Xill·tec™: The milling cutters are available with and without corner radii, with centre cutting edge, reduced neck, protective chamfer, cylindrical and Weldon shank. The universal applicability and an outstanding price/performance ratio make the milling cutters an appealing option not just for sub-suppliers and channel partners, but also for users in a wide range of different sectors.

For more information, please visit http://www.walter-tools.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech