Walter introduces its new MD838 Supreme and MD839 Supreme circle segment milling cutters

Photo by Walter Deutschland GmbH

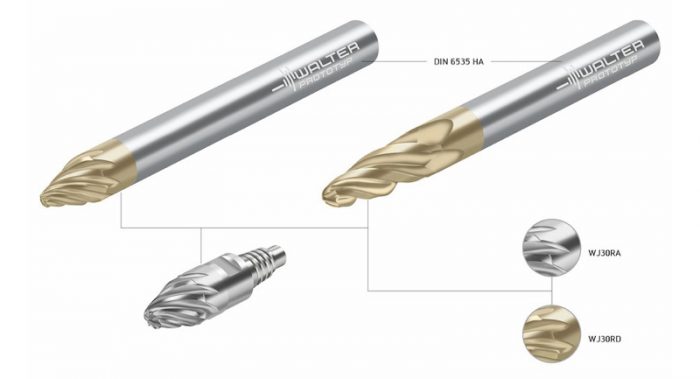

Walter is launching two solid carbide milling cutters especially for finishing operations in the form of the new MD838 Supreme and MD839 Supreme circle segment milling cutters. As is already the case for dynamic milling in roughing operations, with the new milling cutters Walter is unlocking the potential of the latest CAM generation for finishing. This combination results in up to 90 per cent savings on machining time. This is primarily due to the new geometry of the milling cutters, featuring large radii in the cutting area and a higher number of teeth. Thanks to the new tool geometry, large spaces between rows are possible when semi-finishing and finishing. The high surface quality that this achieves is a feature that additionally meets the requirements for finishing operations.

The MD838 Supreme (z = 4–8) has a conical design and boasts an effective radius of 250 to 1000 mm; Walter’s range also includes a version of this tool with ConeFit exchangeable head. The tangential MD839 Supreme (z = 4) with an effective radius of 100 mm is the better choice where space is limited (for example blisk production). The two circle segment milling cutters are available both in the WJ30RD grade, for steel or cast iron materials, as well as in WJ30RA for ISO M and S. Due to their specially developed geometries, both milling cutters are ideal for final machining of components with steep walls, deep cavities, prismatic surfaces and transition radii, for example in the energy industry, in general mechanical engineering, or in mould and die making. Alongside short machining times, their high degree of stability and process reliability, as well as component accuracy and productivity, make them perfectly suited to these applications.

For more information, please visit http://www.walter-tools.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech