Walter releases new Tiger·tec® Gold WSM33G grade featuring exceptional hardness and increased toughness

Photo by Walter Deutschland GmbH

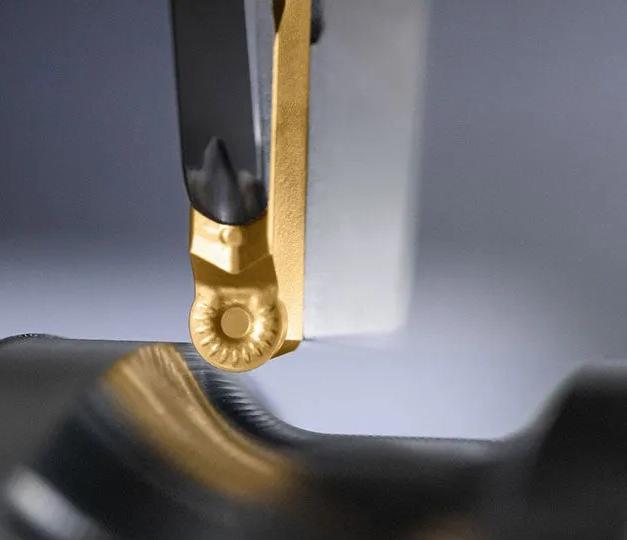

Walter is one of the world’s leading suppliers of precision tools for metal machining. The company is proving this once again with the patent-pending Tiger·tec® Gold WSM33G grade. The WSM33G is Walter’s first PVD grade to be specifically developed for the high loads which occur during grooving. The cutting tool material combines third-generation TiAlN with TiSiN to form a multi-layer coating with exceptional hardness and increased toughness. A special post-treatment reduces friction and ensures a smooth surface, thereby optimising chip removal and process reliability. What’s more, the gold top layer makes it easier for users to detect wear. Walter uses the new PVD coating on single-edged SX cutting inserts with positive engagement and a self-clamping system, as well as on indexable inserts from the double-edged DX18 system, where a second prism ensures stability in the insert seat.

For users, the fact that this grade can be used with both systems means maximum versatility because all insert widths between 1.0 and 10 mm are covered. Another advantage of the Tiger·tec® Gold WSM33G grade is its adaptability – even in challenging conditions. The universal grade can be used for 75% of all applications: Grooving and parting off, groove turning and copy turning or slot milling – whether in steel (ISO P30), stainless steels (ISO M30) or materials with difficult cutting properties (ISO S30). The universal application, long tool life and high resistance of the multi-layer coating against plastic deformation and flank face wear make the WSM33G grooving inserts an incredibly productive and reliable choice.

For more information, please visit http://www.walter-tools.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech