BURKHARDT’S A-AXIS COMPLETELY MODIFIED

Fertigungssysteme GmbH

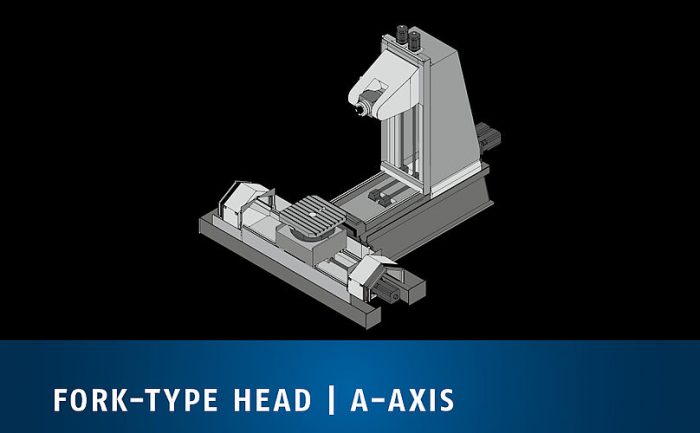

The greatest progress is often made in small steps. After introducing the A-axis, also known as the fork-type head in the MCC machine series, BW has set itself a task of extending this project into the MCX machine series.

The A-axis is thus designed as a full NC-axis. Two versions are available, one as motor spindle with 12,000 min-1 / 300 Nm torque and the other as motor spindle with 6,000 min-1 / 900 Nm torque. The fork head further provides a spindle clamping for the adaption of turning tools for milling and turning machining centres.

Your benefit? Thanks to the design of the fork-type head, it is possible to machine complex or diagonal contours which are difficult to access. In addition, the overhang of the fork head ensures optimum component accessibility even beyond the centre of the pallet.

The A-axis offers flexibility even if it is not used as a continuous axis, but as a pure positioning axis. This becomes interesting when the parts to be machined are less demanding from a geometrical point of view, but rather when it comes to high-precision dimensions between the holes, the rectangularity, surface flatness or requirements to the surface quality.

The A-axis is BW’s answer to when it comes to designing your machines individually and customized.

For more information, please visit: https://burkhardt-weber.com/news

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech