FOOKE TURNKEY SOLUTION REPLACES CONVENTIONAL CHEMICAL MILLING

In aerospace, weight is crucial: every gram saved helps to reduce fuel consumption, improve aircraft efficiency and ultimately reduce CO2 emissions. For this reason, fuselage segments for aircraft and missiles, outer shells of turbines and other aluminium sheets are designed in a specific thickness profile according to their structural load. In load-bearing areas, higher wall thicknesses are used. In areas not subject to high loads, the sheets are reduced to lower residual wall thicknesses to save weight.

In a stretch forming process, flat rolled raw sheets are formed into spherically curved sheets. The subsequent production of the pockets and thus the attainment of the defined residual wall thickness can be achieved by various removal processes.

A complex but still widely used process is, for example, chemical milling. milling, in which sheets are immersed in chemical baths to obtain the desired thicknesses.

obtained. Although this technology is well controllable and established, it has its limitations because of the high and the relatively long duration of the process.

Although many companies are striving to reduce the environmental impact and to shorten the cycle times, the mechanical processing of sheet metal is very complex due to a multitude of influencing complex due to a multitude of influencing factors. Since the thickness tolerance and also the specified geometry are decisive for the final result, the machining of the preformed sheet metal is special attention is paid to the incoming dimensions of the preformed sheet. Deviations caused by handling or forming processes must be reliably be reliably detected. The correct clamping technique, the insertion of the sheet metal into a fixture and the quality of the clamping must be guaranteed at all times.

With these challenges in mind, FOOKE has developed a milling process specifically for this application that does not require the massive use of chemicals and reduces machining time to a fraction.

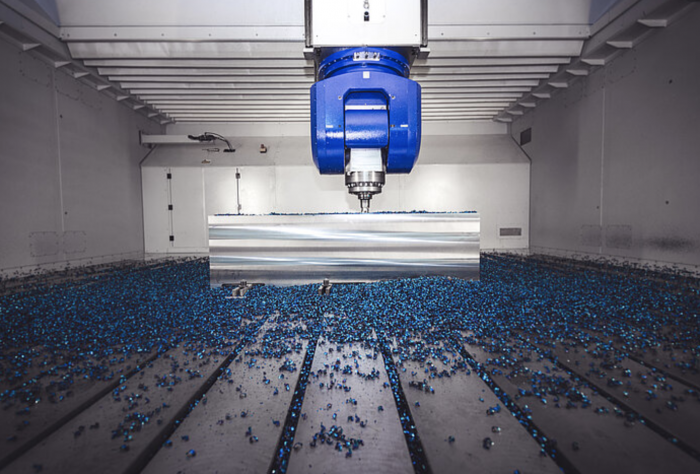

The pre-formed sheets are vacuum-fixed in negative contour – so-called hard-tooling – and the pockets are milled with a high-speed machine. It is not the depth of the pocket that is decisive, but the particularly tight tolerance of the residual wall thickness. FOOKE offers a holistic solution: in addition to a state-of-the-art gantry machine with linear drive, the ENDURA® 600LINEAR, it also includes hardtooling and the entire process of component measurement and compensation.

The manufacture of large, precise and highly dynamic milling machines has been part of FOOKE’s success story for decades. But it is precisely the process of component measurement and compensation, which is based on various measuring methods, with the associated data processing and visualisation, can be emphasised as a decisive core competence of FOOKE. Various measurement routines and complex data processing algorithms for component correction ensure maximum accuracy. Deviations and e.g. deformations of the clamping device can be reliably detected and compensated. The application includes the fully automatic integration of ultrasonic component measurement into the machine control. Also Temperature influences are also detected and taken into account accordingly in the machining process.

Time-consuming adjustments to CNC programs are simply eliminated.

Strict and continuous quality control and documentation meet the extremely high requirements of the aerospace industry. All these competencies combined enable FOOKE to offer the customer a turnkey solution that, compared to other processes such as “mirror milling”, provides significantly higher process reliability at significantly lower investment costs.

This turnkey solution was developed, validated and has been in production since 2020 at a large, well-known aircraft manufacturer in northern Germany, where the weight of a 10m x 2m fuselage is reduced to 50% by pocket milling. Another identical system incl. process was ordered in mid-2022.

For more information, please visit: https://www.fooke-portalfraesmaschinen.de/en/blog-termine

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech