HURCO AT EMO 2023: AUTOMATION AND EASY PROGRAMMING

HURCO enters this year’s EMO stage with a focus on simplifying programming processes and automation. They will show how free-form surfaces for machining can be easily programmed on the machine with the HURCO control and present established systems for parts handling. “Contract manufacturing is about completing orders quickly and reliably. HRUCO supports their customers with machines and software that enable them to do this,” says Sebastian Herr, Head of Application Technology.

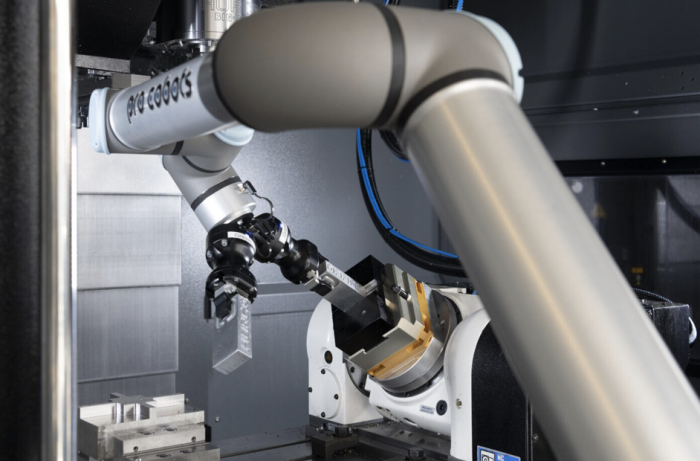

Automation “ProCobots”

We will be presenting the “ProFeeder” solution from our in-house brand ProCobots in Hanover. It can be used on different HURCO machining and turning centres as required. At the EMO, the parts handling system will be on display on the “TM 8 Mi” lathe. The cobot is mounted on a chassis with rollers. It only needs an automatic door, which can be ordered at the same time as new orders and can be retrofitted on many delivered machines.

The ProFeeder is integrated directly into the processes via the user-friendly WinMax software and an Automation Manager developed for ProCobots solutions. “This shows the flexible performance of our control system, whose job manager easily handles the part loading through the automation solution,” says Sebastian Herr. “The Cobot’s software is not required, which eliminates transmission errors and speeds up the work. The operator thus always works in the familiar environment with the two screens. And the screens are the same as always: with lots of pictures and little text as well as all the other features of the WinMax control. It’s fast, dialogue-oriented and covers all the steps to be initiated in automatic parts handling.”

Implement specific automations

As a second handling solution, we are bringing a system from the automation partner Robojob to Hanover. Equipped with a permanently mounted enclosure, it is docked stationary to the “VMX 30 i” machining centre. Similar to the solution from ProCobots, the Robojob system is also fully integrated into the WinMax software and, unlike ProCobots, can be used via the software of the robot system after the start-up installation. Here, the jobs are controlled from the robot system. This also applies to automation solutions from a total of 28 partners with whom we cooperate. In addition to Robojob, these include companies such as EROWA, Kösters or Ecosphere with established standard solutions and companies such as Zorn Maschinenbau, which offer customised solutions as special machine builders. With this partner network, we can realise demand-oriented, economical automation solutions – also for single-part and small-batch production.

Programming free-form surfaces on the machine

The second major topic on our EMO stand is the further simplification of direct programming on the machine. “We want to help our customers to be able to work economically, even when the market is short on deadlines and resources. That’s why our control system is constantly learning,” reports Sebastian Herr. New this year is the “Surfacing” option: with the “Solid Model Import” software option, 3D models that are available as STEP files can be imported directly at the machines. The “Surfacing” option extends this import of solid models to include the surface data set. This means that even complex free-form surfaces can be programmed with the control for machining on the machine. Sebastian Herr: “Until now, you always needed a CAM workstation for free-form surfaces. With our new “Surfacing” function, this can be done directly on the machine, quite simply via the control.”

Visit us at EMO: Hall 12, Stand D68

Other machining centres can be seen on partner stands:

- VM10i Plus 3-axis machining centre at Greenleaf Europe BV (Hall 4, Stand A89) and Air Turbine Tools, Inc. (Hall 12, Stand E12).

- 5-axis machining centre VMX30Di at R. STOCK AG (Hall 5, Stand D23)

For more information, please visit: https://www.hurco.eu

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech