STUDER’s new insertLoad automation solution enables flexible loading and unloading of S33 and S31 machines

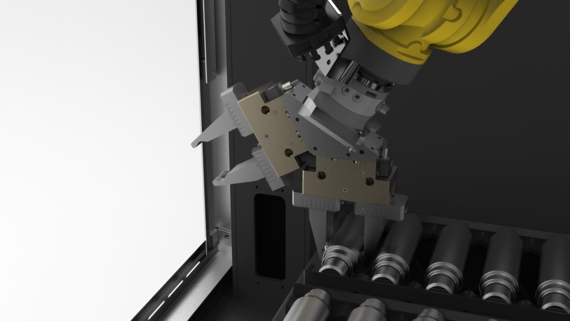

The new insertLoad automation solution supports the loading and unloading of S33 and S31 universal cylindrical grinding machines—and can load workpieces between centers and into the chuck.

Where customized solutions were previously necessary, the new universal loading system from STUDER now enables standardized automation for loading and unloading the S33 and S31. insertLoad can be used for center distances of up to 1,000 millimeters (39.4 inches), thus closing a gap in standardized automation systems. The workpieces can be up to 100 mm (3.94 inches) long and weigh 1.5 kg (3.3 lbs) in alternating mode or 5 kg (11 lbs) in a single mode. The sophisticated design and the ease of use with the digital setup wizard allow users to configure this themselves for centers and chucks – no programming knowledge is required. And insertLoad can handle workpieces that are stored either vertically or horizontally.

The Best Combination of Standardization and Flexibility

The new STUDER loader combines the advantages of a standardized system with great flexibility. It handles a wide variety of parts in terms of geometry, weight, and size; even the capacity of the drawers and the degree of autonomy can be adapted based on the needs and requirements. Loading and unloading is handled by a Fanuc robot, which moves independently on a linear axis between the loader and the machine’s work area. Typically, the time without human operator intervention is between thirty and sixty minutes.

STUDER placed particular emphasis on safety during development. For example, a loading hatch separates the loading area of the insertLoad from the working area of the machine to prevent flame flashback during machining processes using grinding oil. In addition, the software and a safety switch ensure that grinding technicians are not endangered in the event of a deflagration.

Availability for Additional Machines Planned

The insertLoad was presented to the international trade public for the first time at the world’s leading trade show for metalworking, EMO 2023, in Hannover, Germany. Initially, it will only be available for the S33 and S31 CNC universal cylindrical grinding machines, but the availability for other models is in preparation. The S33 and S31 are ideal grinding solutions for small to large workpieces in single, small batches and volume production. Both machines feature distances between centers of 400 to 1,600 millimeters (15.75 to 63 inches) and a center height of 175 millimeters (6.9 inches).

For more information, please visit http://www.studer.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech