„Güllewerk“ has become more flexible and increased heat yield by 30%!

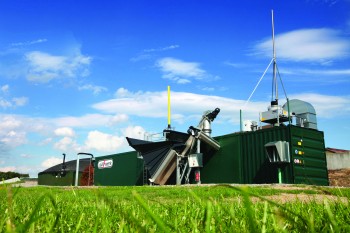

Photo by agriKomp GmbH

As one of the first mini-Biogas plant models, “Güllewerk“ is now well established in the market. The manufacturer, the Franconian agriKomp GmbH, facilitates both the transport and the erection in the future by constructing the “Güllewerk” in two separate containers. The model of success has furthermore been equipped with a sophisticated heat exchanger system.

As early as 2008, the agriKomp developers presented the concept of a small, mobile Biogas plant with the name “Güllewerk” at the “Eurotier” Trade Fair. The concept was often laughed at then, as electricity from mini-slurry plants was not remunerated better than the electricity from large-scale plants. With the entry into force of the German Renewable Energy Resources Act (EEG) in 2012 and the special remuneration for high slurry proportions up to 75 kW, the demand for small-scale plant increased dramatically. “By the end of 2012, around 40 “Güllewerk” slurry plants will be in operation inGermany”, says agriKomp’s sales manager Bernhard Wolf.

Güllewerk plants are already operating highly economically in agricultural holdings across the whole of the federal republic – and that in spite of the majority of these mini-plants starting operation before 2012 and thus not enjoying the new, high scale of remuneration! Whilst the Biogas trade is developing new plant concepts, the Güllewerk has proven itself in the field for almost four years!

Small teething troubles have been sorted out a long time ago, owners’ and operators’ wishes and ideas have been integrated and today a mature product is on display. In the newest version, the digester and technical equipment containers are separated. This facilitates delivery, saves transport costs and increases flexibility in erection. At the same time, the technical equipment container has been increased in size and thus provides the operator further ease of movement.

By means of an optimally positioned system consisting of one low-temperature, and two exhaust heat exchangers, the heat utilisation has been improved! The secret here is a low-temperature heat exchanger which pre-heats the slurry before it enters the digester. By interconnecting with an exhaust heat exchanger, up to 30% more useable heat energy can be achieved – also for heating buildings. Seen in relation to large-scale plants, the Güllewerk is every bit as good.

As an alternative for livestock owners who cannot, or would not want to, use solid manure, agriKomp offers the “Güllekompakt” model from 30 to 75 kW.

For further information visit www.biogastechnik.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech