At the BIOGAS trade fair 2013, Vogelsang presented great repowering products

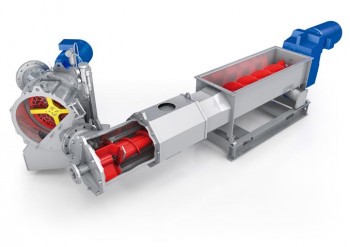

The solid matter feeder system “EnergyJet”

Photo by Hugo Vogelsang Maschinenbau GmbH

Hugo Vogelsang Maschinenbau GmbH, specialist provider of pumping, shredding, distribution and spreading technology for the agricultural, biogas, industrial and municipal sectors, showed two products for improving the efficiency of biogas plants at the BIOGAS trade fair in Leipzig (Jan. 29-31, 2013). Vogelsang demonstrated both the electrokinetic disintegration process using BioCrack and the solid matter feeder EnergyJet which is suitable for introducing a wide variety of renewable resources easily. A smaller version of the EnergyJet, the 30-100 model, was displayed by Vogelsang for the first time at the renergie allgäu e.V. Biogas Info Days in Buchloe (Jan. 16-17, 2013).

Effective substrate treatment with the EnergyJet

Last year the EnergyJet proved in a number of applications that it increases the efficiency of biogas plants due to its reliable and uncomplicated digester feeding, while at the same time being able to handle multiple cosubstrates without any problem. It combines the advantages of fluid and dry solid matter feeding: on the one hand, corn, grass, dung with liquid manure or recirculated material are mashed into a homogeneous organic suspension; on the other, the digesters are fed reliably thanks to its high resistance to foreign matter. Due to its large free passage and high resistance to stones, metal parts and other similar foreign matter, malfunctions hardly occur. This results in smooth operation and, thanks to bacteria-suitable mashing, increased gas yield.

Four BioCrack modules installed on one base

Photo by Hugo Vogelsang Maschinenbau GmbH

BioCrack optimizes the substrate for fermentation

The BioCrack system also improves the profitability of biogas plants. The electrokinetic disintegration process breaks up clumps (aggregates/colloids) in the substrates, making it easier for the bacteria in the digester to reach nutrients in the organic suspension. The gas yield is thereby increased and energy requirements reduced.

More gas, lower costs

“With the EnergyJet and BioCrack system, we offer two excellent starting points for repowering of a biogas plant. The RotaCut represents a third one, which processes the organic suspension by shredding fibrous and coarse matter, thereby ensuring reduced mixer and pump power demand,” says Harald Vogelsang, Managing Director of Hugo Vogelsang Maschinenbau GmbH. “Ultimately, this results in increased gas yield and reduced energy consumption – for our customers this means improved cost efficiency for their biogas plants.”

For more information, please visit www.vogelsang.info

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech