Latest News

High technology and reliability – Specialists in turning

IMT Intermato can boast great competence in the stock removal world, confirmed also by facts: as a matter of fact, more than two thousand plants have already been delivered all over the […]

Deeper and wider machining with the product innovation GARANT HiPer drill

At the international exhibition for metalworking, the EMO 2013, the Hoffmann Group presents its latest products, projects, and developments in Hall 3, Stand B12. One of the highlights is the new GARANT […]

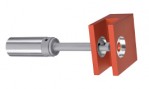

Competitive Solution for Back Spot Faces and Counter Bores

HEULE PRECISION TOOLS launches at EMO their latest development. The new BSF tool extends their range for automated high volume production of back spotfacing and counterboring at an interesting price level. Now, […]

ISCAR has developed the innovative clamping system DOVE IQ-Turn

Rough turning is characterized by high D.O.C. (4-10 mm) and high feed rates (0.4-1.0 mm/rev). Usually large single-sided inserts are used on top-clamp toolholders to withstand interrupted cut and high machining load. […]

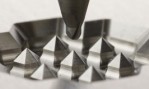

A revolutionary new end mill that “cuts” Cemented Carbide

The new UDC patented Diamond Coating, developed by Union Tool, enables carbide end mills to physically “cut” shapes and features in to cemented carbide work material. By combining optimized cutting geometry, with […]