What Is Robotic Welding?

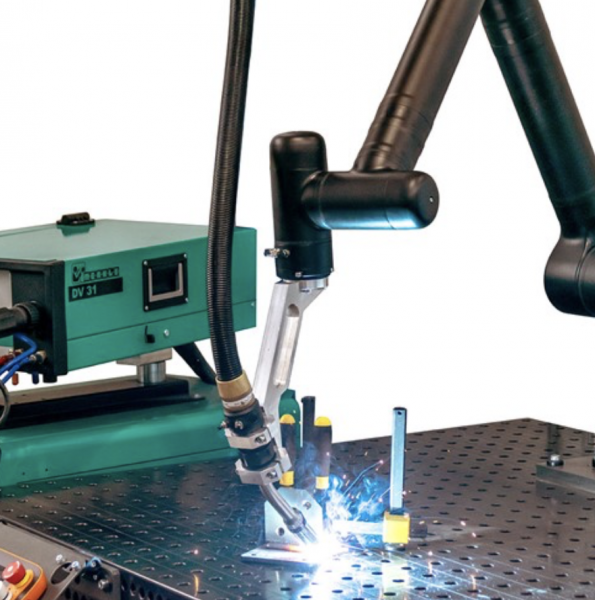

Robotic welding is revolutionizing manufacturing by combining the precision of robotics with the versatility of welding. This technology involves using robotic arms equipped with welding tools to perform welding tasks, offering a range of benefits that traditional methods often cannot match.

What Is Robotic Welding?

Robotic welding utilizes automated robots to perform welding tasks with high precision and repeatability. Unlike manual welding, where human welders execute the task, robotic welding systems are programmed to handle complex and repetitive welding operations with consistent quality.

How Does Robotic Welding Work?

Robotic welding systems typically consist of a robotic arm, a welding torch, and a control system. The robot arm is programmed to move the welding torch along a predetermined path to weld various components together. The system can be designed for different types of welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding.

- Programming: The welding path and parameters are programmed into the robot’s control system. This can involve detailed instructions on the angle, speed, and position of the welding torch.

- Execution: Once programmed, the robot performs the welding task automatically. The precision of robotic arms ensures that each weld is consistent in quality and strength.

- Inspection: Advanced systems often include sensors and cameras to inspect the welds in real-time, ensuring that they meet the required standards.

Benefits of Robotic Welding

- Consistency and Quality: Robots provide consistent welds with uniform quality, reducing the likelihood of defects and rework.

- Increased Productivity: Robotic systems can operate continuously without breaks, increasing production rates and efficiency.

- Safety: Robots handle hazardous welding environments, reducing the risk of injury to human workers.

- Flexibility: Modern robotic welding systems can be reprogrammed for different welding tasks, making them adaptable to changing production needs.

- Cost Savings: While the initial investment in robotic welding systems can be significant, the long-term savings on labor, material waste, and quality control often outweigh the costs.

Applications of Robotic Welding

Robotic welding is used across various industries, including automotive, aerospace, and manufacturing. It is ideal for tasks that require high precision, such as welding components in cars, aircraft parts, and structural elements in construction.

Future of Robotic Welding

The future of robotic welding is promising, with advancements in technology making systems more accessible and capable. Developments in artificial intelligence and machine learning are enhancing the capabilities of robotic welding systems, making them more intuitive and efficient.

Conclusion

Robotic welding is transforming the manufacturing industry by providing consistent, high-quality welds with increased productivity and safety. As technology continues to advance, robotic welding systems will become even more integral to modern manufacturing processes. Whether for large-scale production or specialized applications, robotic welding offers a versatile and efficient solution for today’s manufacturing challenges.

For more information, please visit: https://www.kassowrobots.com/blog

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech