2-in-1 World First: drylin W Hybrid Roller Bearing Combines Smooth Operation with Heavy Duty

igus has developed a maintenance-free hybrid roller bearing with a retraction system for precise adjustment tasks, such as retractable steps in trains.

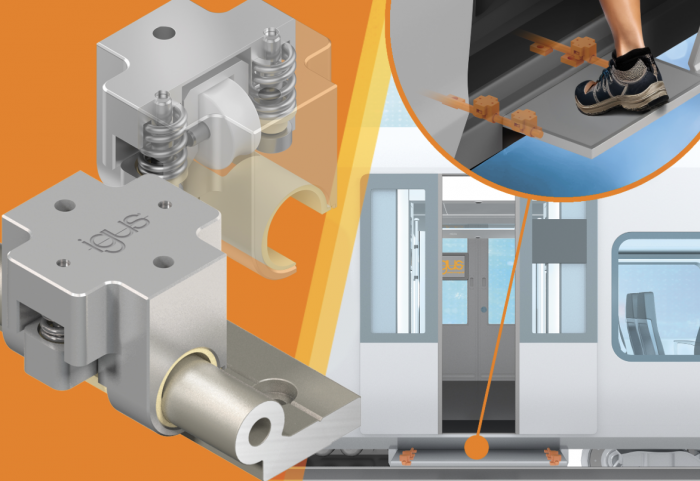

Many designers face a common challenge: they need a guidance system for extension mechanisms that moves effortlessly yet can handle high loads without rapid wear. Examples include retractable steps on train carriages, base solutions in furniture, or laboratory equipment. Traditional lubricated metal ball bearings are unsuitable here due to high maintenance requirements and poor weather resistance. To meet this need, igus has developed the new hybrid roller bearing with a roller retraction system in the drylin W series. Thanks to an innovative design, it combines smooth operation with heavy-duty capability.

Double Functionality: Smooth and Robust

The hybrid roller bearing’s dual functionality—smooth and robust—is achieved through its unique construction: the bearing consists of an aluminum housing that guides a roller. A compression spring pushes the roller with defined preload against the guide rail. In addition, a sliding bearing made of durable high-performance plastic is integrated into the housing.

When a linear carriage moves unloaded over four hybrid roller bearings on a guide rail, the rollers carry the movement. This allows objects mounted on the carriage, such as a train step, to be adjusted with minimal friction and high smoothness, supporting loads of up to 7.5 kilograms per bearing.

Like a Turtle Retracting Its Head

If a high load suddenly occurs—for example, from a passenger’s weight—the spring preload is overcome. The roller lifts off the rail, retracts into the housing, and is protected from localized overload. The main force is then absorbed by the broad contact surface of the polymer sliding bearing, which directly engages the guide rail. Once the load decreases, the roller engages again.

“Thanks to this combination, it is possible to handle temporarily high loads up to 2,100 Newton while maintaining extreme smoothness, without wearing out the sensitive roller of the hybrid bearing,” explains Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “Applications are therefore more reliable and maintenance-free.”

The hybrid roller bearing is now available in size 16. On request, igus supplies the bearings pre-installed in a WWH series roller carriage with a corrosion-resistant aluminum plate for attachments. It is suitable as an adjustable base solution, whether as a step, ladder replacement, or optional seating component in furniture, as well as for yacht and shipbuilding, laboratory equipment, and the growing market for motorhomes and tiny houses.

Hybrid Roller Bearings Endure 76,923 Double Strokes

igus has tested the durability of the new roller bearings in its laboratory. A linear carriage with four bearings was moved along a 1,500 mm rail under a load of 250 N per bearing. The result: the carriage reached 76,923 double strokes before the wear limit was reached.

The maintenance-free high-performance polymers used in the bearings further enhance reliability. Integrated solid lubricants eliminate the need for oil or grease, which could reduce smoothness and increase maintenance due to contamination. Unlike metal bearings, there is no risk of corrosion, making the solution ideal for outdoor use in all weather conditions.

For more information, please visit: https://www.igus.eu

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech