FMB automates the sorting and removal of injection molded parts

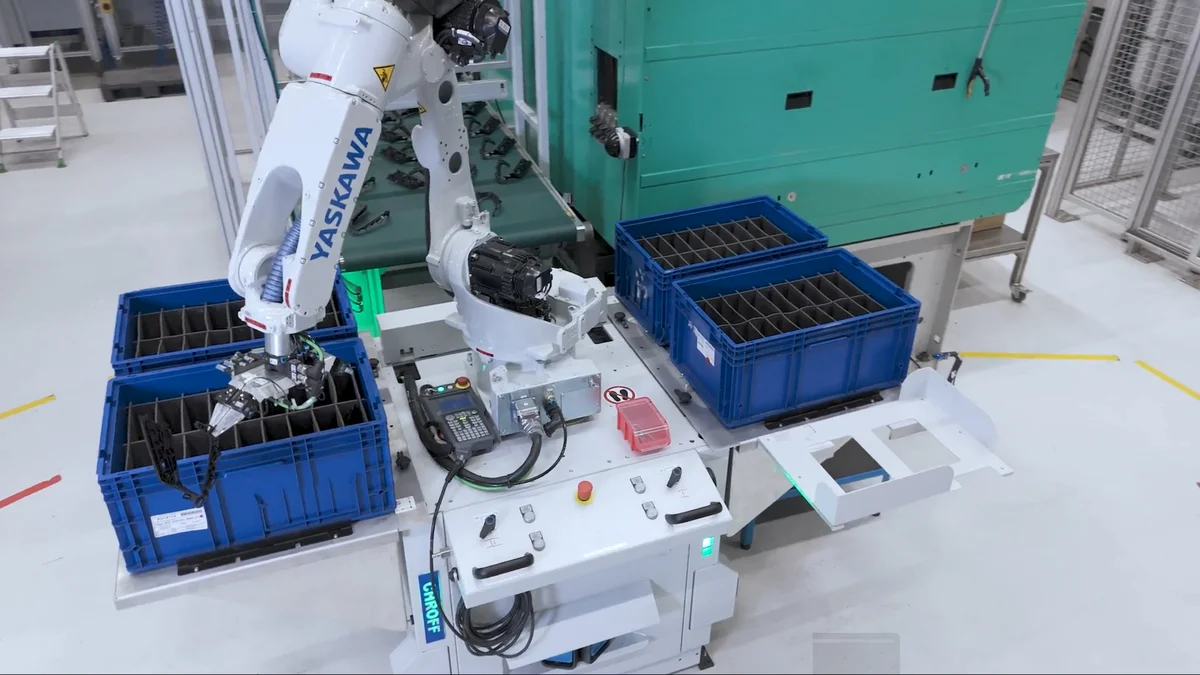

Chroff Kunststofftechnik GmbH, based in Bamberg, specializes in the manufacture of complex, high-quality plastic components for various industries. Injection-molded parts, which are produced in large quantities for a current order, must be sorted after production and placed in KLT containers. Chroff has automated this process with a handling system from FMB Maschinenbau. The modular handling system base from FMB, which is equipped with the Yaskawa GP12 industrial robot, is ideal for this task and can fully demonstrate its strengths.

High-performance camera system

The finished injection-molded parts are conveyed on a conveyor belt and transported to KLT containers provided for this purpose. The complex geometry of the parts and their non-oriented position on the conveyor belt have made subsequent processes difficult up to now. In addition, left and right components are produced by the injection molding machine and run off the conveyor belt together. These must be sorted separately into the correct containers. Until now, a specialist has taken over this task and placed the parts in the appropriate KLT containers.

“The big challenge in automating the removal process was recognizing the workpieces on the conveyor belt,” explains Fabian Schäfer, electrical design engineer at FMB. Michael Vogel, head of technical design at FMB, adds: “FMB has been working with optical systems for component recognition for a long time and has built up a wealth of expertise in this area.” FMB has implemented many projects in the field of randomly stored components and bin picking in recent years. In the process, the company has extensively tested various cameras and vision systems. Given the requirements here, the company relies on Keyence’s all-in-one camera with integrated AI. This transmits all the necessary data to the robot for orienting the components so that it can individually grasp the components at a suitable location. With the support of artificial intelligence, the camera is also capable of performing various checks.

Possible applications include searching for production errors and recognizing text, codes, or colors. Here, the camera checks whether the component is right-handed or left-handed. This information is also sent to the robot. The components are then sorted reliably and correctly into the KLT containers. A Yaskawa GP12 is used for this purpose. With a payload of 12 kg and a reach of 1440 mm, the 6-axis industrial robot is perfectly suited for handling parts and is an established component in FMB’s handling systems. FMB and Yaskawa have a long history together. FMB has been acting as a system integrator for Yaskawa industrial robots for 25 years. Over the years, the two companies have grown together. While the initial focus was primarily on loading and unloading tasks for industrial production, the spectrum is now much broader. Automation is in demand in all industries. Joining and assembly, packaging, measuring, labeling or, as in this case, removing and sorting complex injection-molded parts.

For more information visit: yaskawa.eu.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech