ATI’s new CDB deburring tool offers easy dynamic tuning of contact force

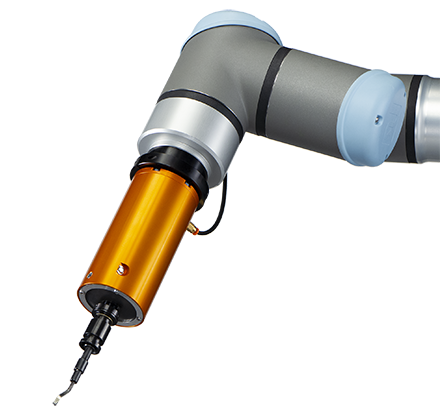

The Compliant Deburring Blade (CDB), patent pending, is ATI’s most versatile deburring tool. The durable interface accommodates a variety of readily available blades and media used with hand deburring tools. The pneumatically-controlled, articulated design gives users the ability to tune the contact force to accommodate specific applications by changing the air pressure. This deburring tool excels in light and medium deburring, chamfering, and scraping operations on materials such as plastic, aluminum, steel, and brass.

The CDB’s axial and radial compliance is ideal for maintaining constant force where surface irregularities are present. Integrating the Compliant Deburring Blade in a robotic material removal application not only reduces robotic programming time, but also makes the programming process easier.

ATI’s CDB is also available with Automatic Blade Changing which gives users the ability to deploy multiple blades in one cycle, or easily store backup blades. The auto-change feature also makes the changeover process hands-free and further increases process efficiency.

The pneumatically-actuated compliance mechanism enables dynamic control of contact force to accommodate a wide variety of material removal applications and is a great replacement for processes that currently use hand deburring blades.

The new Compliant Deburring Blade from ATI is compatible with a variety of robot types, and is particularly well-suited for cobot applications. It is a Certified UR+ Solution and is available as a complete end-effector kit.

For more information, please visit http://www.ati-ia.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech