ATI’s AOV-10 Random Orbital Sander utilized in DIY Robotics’s Robotic Sanding Cell

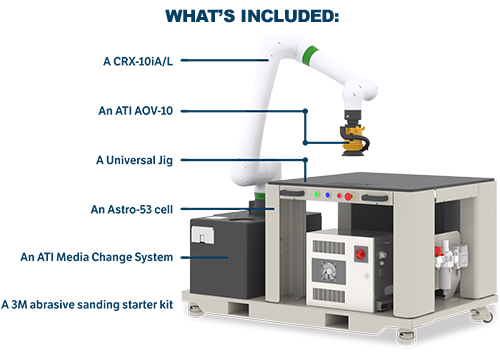

DIY Robotics is offering a turn-key sanding solution to help small and medium-sized businesses bring industrial robotic sanding, finishing, and polishing into their facilities. Called the Robotic Sanding Cell, the solution employs a FANUC CRX-10iA/L robot, ATI’s AOV-10 Random Orbital Sander, and an abrasives kit from 3M. Together, these components prime the Robotic Sanding Cell to offer users exceptional flexibility, performance, and usability.

Sanding is a well-known process to many people, and while it may appear straightforward, many important factors contribute to a successful sanding application—especially when developing an automated solution. Among these factors is the choice of robotic end-effector. Without the ability to detect variations in the surface of parts, robots rely on their end-of-arm tooling to comply with irregularities and maintain contact with a work piece. To satisfy the need for compliant end-of-arm tooling in their Robotic Sanding Cell, DIY chose ATI’s AOV-10.

With a compact, rugged design, powerful vane motor, and adjustable, built-in compliance, the AOV-10 brings the right combination of performance and flexibility to DIY’s sanding solution. Optimized for 3M abrasives, the AOV-10 can accommodate a wide variety of sanding and finishing media, making it easy for users to find the right finish for their part.

To help eliminate the need for manual changeover of media, the Robotic Sanding Cell ships with the AOV-10’s Automatic Media Exchange System. This system allows for the hands-free exchange of media, making the process a fully automated operation and removing workers from the dull, dirty, and dangerous aspects of sanding applications.

For more information, please visit http://www.ati-ia.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech