Xeikon’s 3000 series: Digital and flexographic printing in perfection

The end-user market for label and packaging applications has seen tremendous transformation in the recent years. This has been mainly fueled by the need for more versions, creating a greater variety of choice amongst the brand owner’s product lines. This creates new challenges for the manufacturing processes, which also impact the printing industry. Major trends include faster turnaround, more product launches, varying order quantities amongst the varieties resulting in a greater demand for flexibility, transparency while facing challenging economics. Therefore, label printers are diversifying the production capabilities by adding digital presses next to their flexo presses. This enables them to produce shorter runs profitably, create more flexibility in their production workflow and be more competitive.

e Xeikon 3000 Series of digital presses

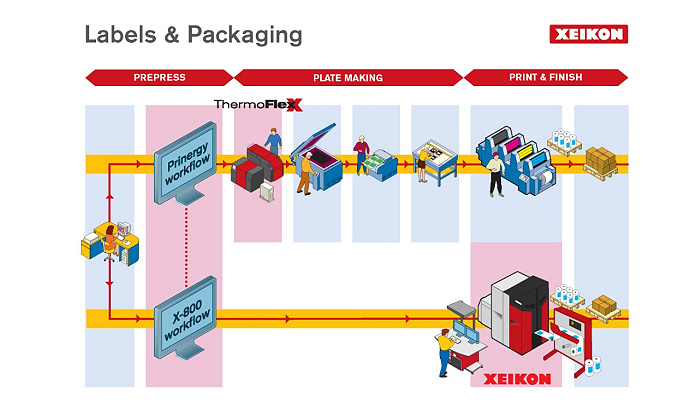

Xeikon believes that flexo printing and digital printing are complementary technologies and both have a bright future. Therefore, Xeikon expanded its offerings with ThermoFlexX imagers for flexo and letterpress plates, alongside the Xeikon 3000 Series of digital presses.

To optimize the productivity and flexibility of their operations, flexo and letterpress printers want to bring all the necessary production steps under their own control. As a result, they need in-house flexo and letterpress plate production solutions including professional digital imagers, a flexible workflow to manage the whole operation, all the necessary finishing systems and consumables, as well as appropriate service support to guarantee reliable production. The main decision criteria for these investments are enhanced quality, better image control, modularity and cost optimization.

Similarly, repro companies need increased efficiencies and throughputs to meet the demands of brand owners and print professionals. They too need imaging solutions that can achieve higher quality, workflow flexibility, modularity and cost efficiency.

With its wide range of ThermoFlexX imagers, Xeikon combines quality, cost and time savings as well as operator convenience with unique features, such as 5080dpi resolution and the Vacuum Slider Concept (VSC).

At the same time, using digital and flexo technologies side-by-side does create new challenges. In general, digital technology has a superior image quality compared to flexo. If a printer wants to allocate their jobs to a digital or a flexo press based on run lengths, they need to make sure that the final product has the same look and feel. The flexibility of the digital printing technology has the intrinsic capability to modify/alter the print quality creating a look-alike of flexo quality. Consequently, it achieves a result where only a limited difference can be noticed between flexo and digitally printed label.

It all starts with the substrate. Having the ability to use the identical material on flexo and digital presses takes one of the greatest variables out of the equation. Xeikon dry toner provides a perfect answer in this regard as no special pretreatment or pre-coating is required to make the material printable.

Secondly, the screen rulings used on the digital press need to be adjusted, making it compatible with flexo.

Digital and flexographic printing complement each other, while serving specific application requirements

A third important step is to use color management. Several different procedures can be setup based on the production workflow of label printers, wherein they can create a color profile for both flexo and digital on all their presses. This color profile describes the color capabilities of the press using a specific material and specific inks/toner. Implementing both press profiles in the workflow will allow colors to match across the different printing technologies.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech