Efficiency for plastic by Baumüller

In the industry over two thirds of energy consumption is taken by electrical drives and it is for this reason that machine makers are investing more and more in efficient systems. Baumüller offers its motors with appropriate drive electronics and control technology as well as pre-programmed software modules and consistent total systems for more efficiency in virtually all application areas.

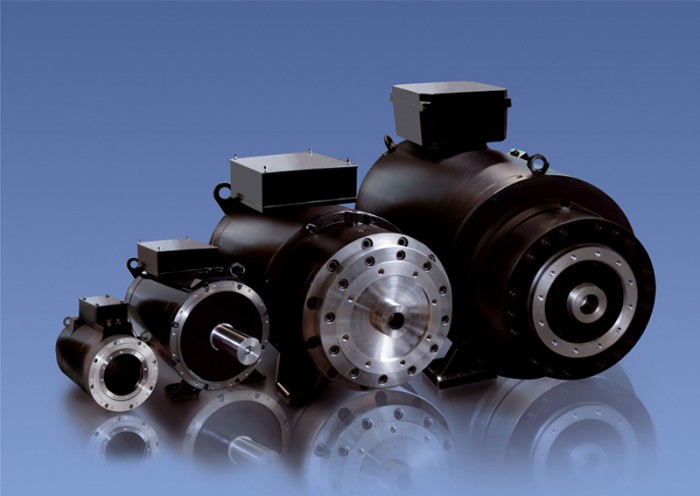

With the Baumüller high-torque-motors we obviate gearbox losses and maintenance work, the efficiency of the machine therefore increases tangibly

Photo by Baumüller

With the servo motor ranges DSC, DSP and DSD2 and the High-Torque motors DST and powerful synchronous motors, Baumüller will be presenting a broad portfolio of compact and efficient motors for various different applications at the K exhibition. The servo motors, that are available uncooled or cooled with air or water, are convincing with very smooth running characteristics and a particularly slim housing design. The DS2 synchronous motors, all-rounders that can be used in a particularly flexible manner, can now also be supplied by the manufacturer with an optimised water cooling concept. This achieved an increase in efficiency and machine builders have the facility of selecting smaller sizes with the same output and thus saving space. In this range we were also able to achieve an increase in speed to 4300 min-1. With the DST High-Torque motors Baumüller offers a direct drive technology for the most stringent of torque demands to 32000 Nm.

The b maXX 5000 converter generation is also available as a mono unit with a wide range of cooling variants, including water-cooling. In order to increase the energy efficiency, the converter variant b maXX 5100 is also available as a feedback unit, with which braking energy is fed back into the mains instead of being lost as heat.

With the servo pump, Baumüller achieves enormous energy savings in injection moulding machines, for example

Photo by Baumüller

Modernisation without adaptations in the control system

With the servo pump concept, Baumüller is presenting the star in the field of energy efficiency in the plastics industry. In the combination of servo drive and constant pump, the benefits of electric power regulation and hydraulic power transmission are united. This means that developers can achieve a high level of efficiency, with, at the same, a significant reduction in energy consumption. Based on the higher dynamic levels, compared to regulating pumps, the cycle time reduces and the output of the machine increases. In the modernisation of existing installations, no adaption to the control system is necessary, because the classic set values of the regulating pump can be processed by the integrated pump regulation in the converter.

Both for the servo pump and for all other standard movements in plastics machines, Baumüller offers many pre-programmed and validated software modules. This clearly reduces the development involvement by the machine builder and the costs and the time-to-market reduce.

For further information, please visit: www.baumueller.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech