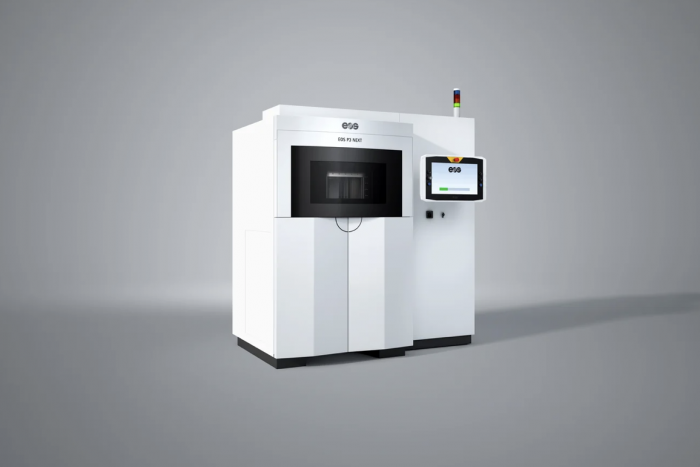

EOS Levels-Up Polymer Additive Manufacturing with the Introduction of the EOS P3 NEXT

EOS, a leader in sustainable manufacturing solutions and a pioneer in selective laser sintering (SLS) 3D printing technology, made a strong start at Formnext 2024 by unveiling the EOS P3 NEXT industrial 3D printer, setting new benchmarks in productivity and efficiency for its polymer customers.

“We listened to our customers and the market and delivered what we believe sets the new benchmark for midframe serial polymer SLS production. The EOS P3 NEXT is an exceptionally productive machine, and when combined with remarkable new materials – such as EOS PA 2220 HighReuse and ALM PA 950 HD, which require minimal refresh, the EOS P3 NEXT makes the strongest case yet for SLS for in-mouth devices, eyewear, surgical guides, structural components. Our polymer solutions have a strong medical legacy, having been successfully deployed by numerous customers for more than two decades.”

Virginia Palacios, Chief Business Officer – Polymer, EOS

One EOS customer exploring the EOS P3 NEXT’s potential is ADDMAN Group, a leading U.S.-based AM service provider with more than 500 employees:

“Seeing the EOS P3 NEXT in action really solidified it for me—this is exactly the technology we need to meet the high standards of our medical manufacturing customers. The EOS P3 NEXT allows us to produce applications for the regulated medical market within a fully certified production environment, ensuring we meet both quality and compliance benchmarks. ADDMAN and EOS have a well-established partnership in metal 3D printing, and we are excited to expand this collaboration into the realm of SLS polymer. As the workhouse technology for our new Health Excellence Additive Lab (HEAL) Center launching in Florida in January 2025, the EOS P3 NEXT will empower us to deliver unmatched quality and cost-effectiveness for our medical manufacturing partners, reinforcing our commitment to excellence in this critical industry. ”

Jay Dinsmore, Executive Vice President, ADDMAN

With its integrated monitor, the EOS P3 NEXT casts a slightly smaller overall footprint than the prior EOS P 396, requiring less floor space yet maintaining the same build volume (340x340x600mm). The biggest changes lie under the hood: advanced software updates and scanning algorithms, improved recoater speed, optimized heating, and new peripheral equipment, providing:

- Increased productivity: An optimized process sequence with accelerated pre-scanning, recoating and cool down, resulting in up to 50% increase in productivity

- Higher Machine Utilization: Up to 90% machine availability ensuring that machine, labor and floor space are used efficiently while driving operational excellence

- Improved Material Efficiency: 80% material reusability with ALM PA 950 HD nylon 12 material; 70% material reusability with EOS PA 2220 HighReuse

- Lowered TCO: Up to 30% reduced of total cost of ownership

- Enhanced Part Quality: Increased dimensional accuracy, surface finish and mechanical part properties with flexible parameter adjustment capabilities and material variety

- User-friendly print-to-part workflow: Streamlined production processes that include unpacking and finishing of parts as well as sieving, and mixing of materials, ensuring safe and efficient operations

- Regulated Markets Readiness: Biocompatible material, field-proven technology, EOS qualification services & quality assurance procedures

“Faster, more efficient, and enabled by new materials, the EOS P3 NEXT opens up new possibilities for tool-free manufacturing. This system provides an end-to-end manufacturing solution for users, streamlining the production process and creating a more user-friendly interface for operators. Regardless of AM experience, this system makes it easy to be successful with industrial polymer 3D printing.”

Alexander Prillwitz, Product Manager, EOS P3 NEXT

For more information, please visit: https://www.eos.info/press-media/press-center/press-releases#2024

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech