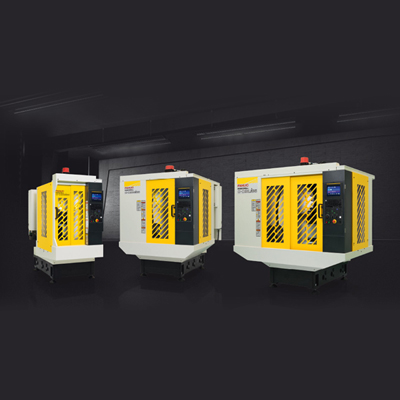

Fanuc introduces its new ROBODRILL machines

Photo by FANUC Luxembourg Corporation

Fanuc announces the new generation of ROBODRILL machines, which was presented at the AMB Show in Stuttgart.

The new α-DiB series will take over from the successful α-DiA series. It comes with a variety of improvements and new features. The biggest change is the introduction of advanced machines.

With the new series, Fanuc offers both standard and advanced models in the known sizes (S, M, L). So there are six ROBODRILL machines to meet the needs of customers.

Both the standard and advanced models have an operator`s panel equipped with the new iHMI to make them easy to use. The Operation Management Software ‘ROBODRILL-Linki’ permanently monitors the machine, providing operation results as they occur. Automatic machine monitoring keeps downtimes to a minimum.

In line with Fanuc’s philosophy, the new ROBODRILL can be easily automated with FANUC Robots. Our ‘Quick & Simple Start-up Package’ simplifies the automation of the ROBODRILL with a FANUC Robot, saving customers time and money.

Fanuc has reduced cycle time by using new smart functions for rapid traverse and tool changing. Also, the new machines have been designed to make maintenance even quicker and as easy as possible, thanks to an improved Preventive Maintenance Guidance feature.

Starting 2017, all models can be equipped with the new DDRiB rotary table or DDR-TiB trunnion system with an indexing time of 0.55 seconds – a reduction of 0.3 seconds – and very fast clamping. The clamping torque has been increased to 700N-m.

The advanced α-DiB models offer the following extra technical improvements.

- Z-axis strokes reach 400mm to produce larger parts, reducing the interference among tools and the workpiece.

- An extra servo motor has been installed in the turret to reduce the tool-change time to 0.7 seconds – 0.2 seconds faster than the standard version – for faster cycle times and increased productivity.

- Advanced models now accept larger tools of up to 4kg.

For more information, please visit http://www.fanuc.eu.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech