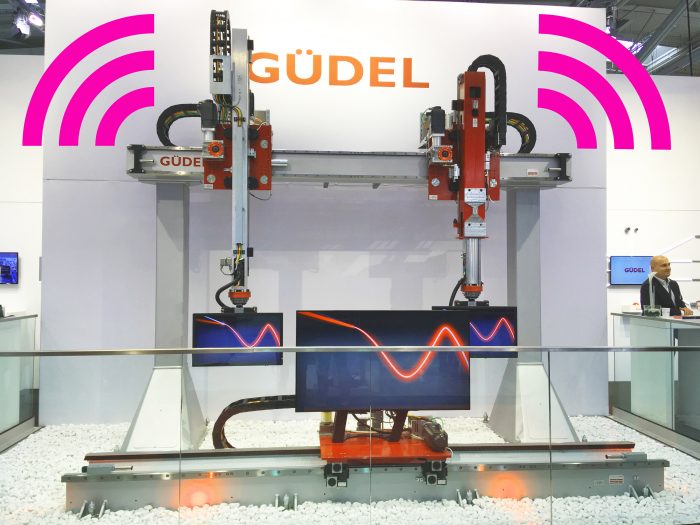

Güdel linear robots even more productive with intelligent energy supply thanks to igus

Planning maintenance in advance: This goal is not only being pursued by igus with its intelligent smart plastics products for monitoring energy chains, cables and plain bearings, but manufacturers of machines and systems are also increasingly offering solutions with their own condition monitoring tools. One of these companies is the Swiss company Güdel: The automation specialist uses the igus sensors EC.M and EC.W for its linear robots. “The sensors measure the movement and wear of the four energy chains used and send the measured values via the icom data concentrator to Güdel’s condition monitoring computer,” explains Richard Habering, head of the smart plastics division at igus. The connection to the igus cloud enables the data to be evaluated using AI and machine learning. The analysed data is integrated via the Güdel condition monitoring system. “With the tool, the user can monitor the condition of the energy chains used and the rollers during operation,” says Daniel Bangerter, Head of Customer Care at Güdel. “By recording and evaluating the data, maintenance can be planned”.

In the video (https://youtu.be/oYRlQR1Ny5s) Richard Habering and Daniel Bangerter explain how exactly predictive maintenance works with smart plastics and the condition monitoring system from Güdel.

For more information, please visit: https://www.igus.com/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech