HARTING RFID offers an optimized solution for railway application

RFID for the railway

Photo by HARTING Technology Group

Railroad engineering, otherwise known as a rather traditional branch of industry, is currently showing itself as very innovative in a consistent process of modernization of production, maintenance and signaling. In this context, RFID is proving itself as a key technology, since RFID from HARTING is robust, long-lived, maintenance free and reliable.

The railway area presents some very special challenges with regard to the technologies involved: extreme environmental demands (especially on the bogies), stone impacts, vandalism, very high speeds, reliability over decades with rising cost pressure as well as tight schedules for maintenance.

HARTING has ranked as the railway connector specialist for decades. Over recent years this valuable experience has been consistently transferred to the HARTING RFID products. Tests like the EN 50155 railway standard are therefore nothing new for us, but familiar terrain.

HARTING offers an entire range of solutions here; for example, in the area of servicing and maintenance. The maintenance of trains is safety-critical and expensive at the same time. A train in the maintenance shop cannot earn any money. HARTING offers mobile apps for configuration and maintenance management. These mobile solutions simplify the work, make the process transparent and thereby increase safety, while saving time and costs at the same time.

There are also additional requirements: Modern commuter trains are sometimes longer than the platform, or the platform has additional safety doors. In both cases, the train has to be positioned precisely, and only particular doors may be opened. RFID is a very robust and simple means, despite dirt, dust, leaves, rain and stone impacts, for stopping a train precisely by the platform and for providing the onboard electronics with a signal showing which doors have been opened and which have not. Since the transponders can also be hidden in concrete, the solution is well protected from manipulation and vandalism.

Touristically attractive old towns have to struggle with overhead conductors, which are sometimes not very attractive. At the same time, the number of trams and buses with electric drive systems is increasing. HARTING RFID offers the possibility of informing the tram that it is approaching a charging station and thereby avoiding the loss of a single second of charging time, since all systems are already prepared. In addition, the precise location can easily be determined so that the vehicle knows whether an overhead line for charging is available or the battery has to be used for propulsion.

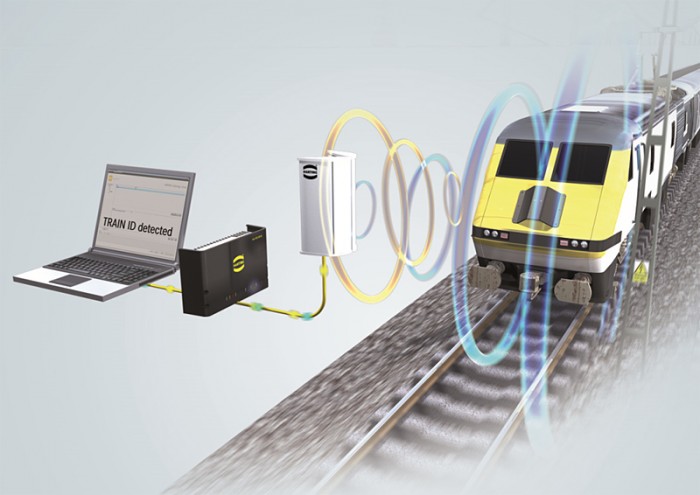

RFID also allows data recording from fast moving trains. Customers have successfully tested the complete RFID systems – from extremely robust, metal-housed transponders to connection with the software, and easily recorded data from trains at over 120 km/h. Here, the transponders are mounted on the train and the RFID reader may be tested in a switching cabinet mounted near the track in conformity with railway standards. The Internet also provides evidence of instances in which even speeds of 200 km/h can be managed without problems.

For more information, please visit http://www.harting.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech