Heraeus expands the usage of Aerosol Deposition coating method for industrial applications

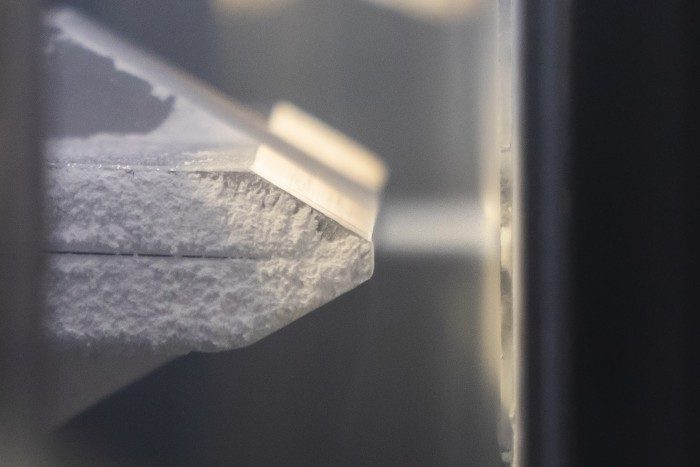

Photo by Heraeus Sensor Technology

Heraeus broadens the application range of the Aerosol Deposition coating method. So far, the technology, which was developed in Japan, has been used mainly in Asia for coating of components for plasma etch chambers. Although the coating method offers many advantages, other industries have hardly applied it until now. “However, feasibility studies by universities such as the University of Bayreuth have shown that Aerosol Deposition offers advantages also for other applications,” Dr. Ilka Luck says, Head of Heraeus High Performance Coatings. She sees potential in sensor technology, power electronics, battery, and medical technology, among others.

“We have worked intensively over the past two years on optimizing processes and machines for production on industrial scale. As a result, we are the only supplier that accompanies customers all the way from feasibility study to series production,” Luck comments. The technology is particularly promising when conventional methods do not achieve the required quality, or the desired coating cannot yet be produced at all.

Aerosol Deposition is a process for producing thin material layers. Material particles are accelerated to a speed of several hundred meters per second with the aid of a carrier gas. These then hit a surface, the so-called substrate, where they form a closed film.

High-performance coatings

Aerosol Deposition has no fundamental limitations in terms of coating materials or substrates that can be used. “We already use both for coating, metals and ceramics. The only requirement for its use is that the material is available as a processable powder,” Luck explains.

The resulting coatings from 1 µm thickness on are characterized by material properties that come close to those of the volume material. At the same time, they exhibit high density and adhesion. “The good adhesion is due to the fact that the substrate and the layer form a chemical bond where they meet,” Luck says.

Depending on the material used, coatings applied by Aerosol Deposition can be used as electrical insulation layers, heat-conducting layers, corrosion and abrasion protection, adhesion promoters, for surface finishing and even as free-standing metal layers.

New material combinations

Unlike coating technologies such as thermal evaporation, Aerosol Deposition can be done at room temperature – ideal for materials and substrates that are not temperature resistant. Neither material nor phase transformation occur during deposition on the substrate. This enables completely new combinations of coating and substrate. Heraeus has already successfully tested a wide range of substrate materials, including steel, ceramic, glass, plastic, silicon and indium phosphide wafers.

Process advantages for manufacturers

Alternative methods such as sputtering or thermal evaporation must be carried out in a high vacuum, a technically complex and time-consuming process. Aerosol Deposition is often not only faster but is performed in low vacuum and at room temperature. Thus, the new method achieves high deposition rates.

For more information, please visit www.heraeus.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech