kassow robots: How much does a robot cost?

Navigating the complex landscape of robotics integration can be challenging, particularly when considering the diverse costs and technical specifications involved.

The question, “How much does a robot cost?” is difficult to answer definitively, as various factors such as technology, application, and design play a significant role in determining the price.

This article explores the intricacies of robot pricing, offering a clear and detailed breakdown of the associated costs.

Understanding these key elements enables better decision-making aligned with budget and operational objectives.

The discussion will cover specifics on managing these investments effectively.

KEY TAKEAWAYS

Cost Influences

- Technology Level: Advanced technologies like AI, machine learning, and real-time data processing significantly increase a robot’s cost.

- Design Customization: Custom features tailored for specific tasks or environments escalate costs due to specialized design and production requirements.

- Application Specificity: Robots designed for specialized industries or critical tasks often have higher price tags due to the necessary capabilities and certifications.

Types and Costs

- Industrial Robots: Essential for tasks like welding and assembly, typically priced between $25,000 and $400,000 depending on functionality and sophistication.

- Cobots: Designed for safe interaction with humans in shared spaces, generally costing between $15,000 and $45,000, reflecting their accessibility and technological features.

- Cartesian Robots: Ideal for precise linear motions, used in applications like 3D printing, with prices ranging from $10,000 to $50,000 depending on size and precision capabilities.

- Humanoids: Advanced robots mimicking human behavior, significantly more expensive, usually starting at $100,000 and exceeding $1 million, due to high-level AI and mobility technologies.

Considerations

- Application Suitability: Ensure the robot’s capabilities align with the intended tasks and operational demands.

- System Compatibility: Evaluate integration needs with existing systems to avoid additional costs for modifications.

- Maintenance Expenses: Consider ongoing maintenance costs, availability of parts, and technical support for sustainable operations.

- Training and Integration Costs: Allocate resources for training on the proper use and maintenance of new robotics systems to ensure safety and efficiency.

- Adaptability and Longevity: Robots that can be easily reprogrammed or upgraded offer better long-term value by adapting to changes and extending their useful life.

- ROI Metrics: Define metrics to assess the return on investment from robotics, considering financial returns as well as improvements in quality, efficiency, and customer satisfaction.

What Influences the Price of a Robot?

When purchasing a robot, it’s crucial to understand the factors that contribute to its cost.

The price can be significantly affected by the robot’s design complexity, materials used, technology incorporated, and its intended application.

Factors such as task precision, software requirements, and additional features like sensing and vision systems also play a role.

For detailed insights on specific models, like the 7-axis collaborative robots from Kassow Robots, each specification adds layers to the cost.

Technology and Software

The sophistication of a robot’s technology and software greatly influences its price. High-end robots incorporate advanced algorithms for pathfinding, autonomous decision-making, and machine learning, requiring substantial investment in research and development. Additionally, user interface software that enhances the robot’s usability and functionality also adds to the cost. These systems must be continually updated and optimized to handle complex tasks and easily interact with human operators and other automated systems. The integration of IoT connectivity and real-time data processing capabilities further escalates the price, making the robot more adaptable and efficient but also more expensive.

Design and Customization

The level of design and customization involved in a robot’s creation directly impacts its cost. Robots designed with specific requirements for particular industrial tasks, such as extra limbs, specialized tools, or enhanced mobility features, require unique engineering and design solutions. Each custom feature needs to be planned and tested, which increases the research and development cost. Additionally, specialized designs often necessitate the use of unique components and technologies not typically found in standard robots, driving up manufacturing complexity and costs. This custom engineering ensures the robot can perform designated tasks efficiently but also results in a higher price tag due to the increased labor and material costs involved in its production.

Material and Build Quality

The choice of materials in robot construction is critical, as it affects both the durability and functionality of the robot, influencing its cost. High-quality materials that can withstand stress, wear, and environmental conditions are essential for ensuring the robot’s longevity and reliability. These materials often come at a premium, especially when they are lightweight yet strong metals or composites offering superior performance. Additionally, the precision required in machining and assembling these high-grade materials increases manufacturing costs. Robots built with less expensive materials may reduce upfront costs but could lead to higher maintenance expenses and shorter lifespans, potentially increasing overall costs in the long run.

Application and Industry

Robots are increasingly tailored for specific industries, which can affect their costs. For instance, robots designed for the healthcare sector may require precise and gentle handling capabilities, sophisticated diagnostic tools, and compliance with strict regulatory standards. Similarly, robots used in manufacturing might need to handle heavy loads, perform at high speeds, and operate continuously. These specialized capabilities necessitate advanced technology and robust construction, raising costs. Furthermore, the critical nature of tasks performed by these robots often requires extensive safety features and redundancy systems, further increasing their price.

PRODUCTION VOLUME AND ECONOMIES OF SCALE

The cost of robots is significantly influenced by production volume. Robots produced in limited quantities tend to be more expensive per unit because they lack the cost advantages that come with economies of scale seen in mass-produced models. Custom or low-volume robots often require specialized assembly processes and unique parts, which are more costly than those used in high-volume production. On the other hand, large-scale production reduces the cost per unit due to more efficient manufacturing processes and bulk purchasing of materials. Therefore, companies planning extensive use of robots may find it more cost-effective to invest in models produced on a larger scale.

RESEARCH AND DEVELOPMENT COSTS

The cost of robots is also impacted by the investment in research and development (R&D). Developing advanced robotic technologies demands significant R&D resources to create, test, and refine complex systems. This includes expenses related to prototyping, simulation, and field testing to ensure that the robots meet specific performance standards and safety requirements.

REGULATORY COMPLIANCE AND CERTIFICATION

Robots often need to comply with various regulatory and safety standards, which can vary depending on the industry and region. Meeting these regulations can involve additional costs for certification processes, modifications to meet legal requirements, and ongoing compliance monitoring. For instance, robots used in pharmaceutical or food production must adhere to stringent standards, further increasing their overall cost.

TRAINING AND SUPPORT SERVICES

The complexity of modern robots often necessitates training for end-users, and the cost of providing these training programs, user manuals, and technical support can be substantial. Ongoing support services, including maintenance and updates to both software and hardware, also contribute to the total cost of robot ownership.

SUPPLY CHAIN AND LOGISTICS

The final price of a robot is affected by the cost of parts and the complexity of supply chain logistics involved in sourcing and assembling these components. Factors like fluctuations in material costs, tariffs, transportation fees, and supply chain efficiency all play a role in determining costs. Establishing and maintaining a robust supply chain is crucial for timely and cost-effective production but can be expensive.

BRAND AND MARKET POSITIONING

The reputation and market positioning of the robot manufacturer also influence pricing. Established brands with a history of reliability and excellent service might charge a premium for their products. Pricing strategies can also vary based on market positioning, with some brands offering cost-effective solutions, while others target the luxury or high-performance segments of the market.

TYPES OF ROBOTS AND THEIR PRICE TAGS

INDUSTRIAL ROBOTS

Industrial robots are vital in modern manufacturing, performing tasks like welding, painting, and assembly with precision and efficiency. The cost of these robots is influenced by factors such as payload capacity, reach, speed, and the level of required customization. Basic models typically include a controller and basic software at lower prices, while more advanced models with higher payload capacities, extensive customization options, and enhanced capabilities command higher prices. This broad price range (from $25,000 to $400,000) caters to businesses of all sizes, from small manufacturers to large enterprises with heavy-duty requirements.

COBOTS

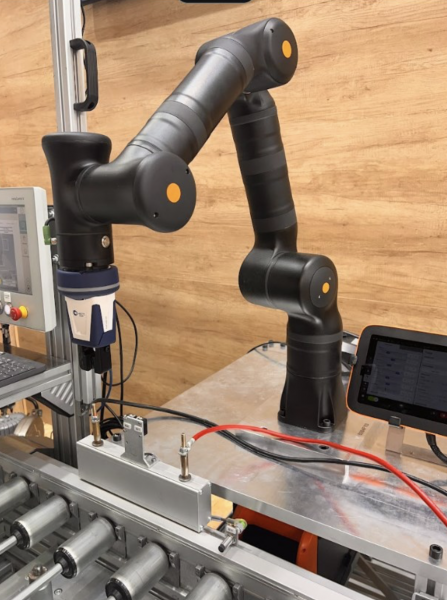

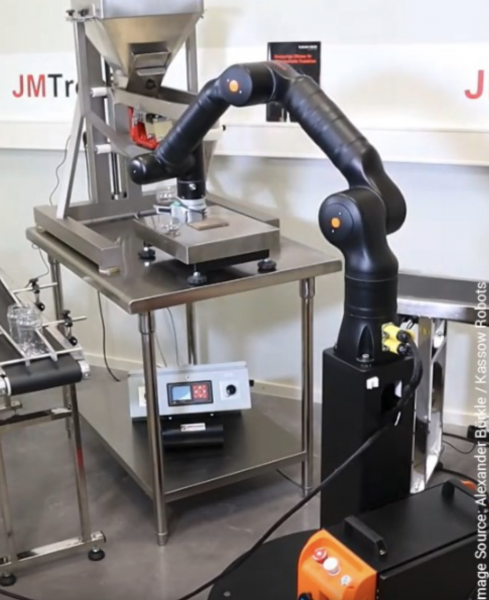

Collaborative robots, or cobots, like the Kassow Robots 7-axes cobot, are designed to work directly with human operators, prioritizing safety and flexibility in shared workspaces. Unlike traditional industrial robots, cobots come with advanced sensors and safety features, allowing safe operation without protective barriers. The cost of cobots varies based on their design, payload capacity, and the complexity of tasks they are programmed to perform. Simpler models for light duties are less expensive than more advanced models equipped with high-tech features like vision systems and enhanced learning capabilities. This price range ($10,000 to $50,000) reflects the growing market for robots accessible to small and medium-sized enterprises, not just large manufacturing facilities.

CARTESIAN ROBOTS

Cartesian robots, defined by their three primary axes of movement—X, Y, and Z—are ideal for precise linear applications such as 3D printing, CNC machining, and assembly operations requiring high accuracy. Their straightforward design generally makes them more affordable than more complex robotic systems. Prices for Cartesian robots typically range from $10,000 to $50,000, with basic models being less expensive than those with greater reach, load capacity, precision capabilities, and customized control systems. This cost range suits industries that require precise, repetitive movements in a controlled environment.

HUMANOIDS

Humanoid robots represent some of the most technologically advanced types of robotics, designed to mimic human motion and interaction. These robots utilize sophisticated AI, machine learning algorithms, and sensory systems to navigate complex environments and perform a variety of tasks. Due to the advanced technology involved, humanoid robots are typically the most expensive, with prices ranging from approximately $100,000 to $1 million. The most advanced models, equipped with cutting-edge features, command the highest prices. These robots are primarily used in research, healthcare, and service industries where human-like interaction and adaptability are crucial, reflecting the significant investment required for their development and deployment.

WHAT TO CONSIDER BEFORE BUYING A ROBOT

Before purchasing a robot, it’s crucial to define your specific needs and consider factors like compatibility with existing systems, long-term costs, and potential operational improvements. The following considerations can help ensure that the robot aligns with your operational goals, providing efficiency, compliance, and a solid return on investment.

DEFINE THE PURPOSE AND REQUIREMENTS

Start by clearly defining the tasks the robot needs to perform, whether it’s assembly, packaging, inspection, palletizing, labeling, or quality control. This will help determine the type of robot needed, such as industrial, collaborative, or service robots. Different tasks require varying levels of precision, speed, and payload capacity, so aligning the robot’s capabilities with your business needs ensures you select the right model without overspending on unnecessary features.

COMPATIBILITY WITH EXISTING SYSTEMS

Assess the compatibility of the new robot with your current machinery and software systems. Ensure that the robot can integrate seamlessly into existing production lines or work environments. Verify if additional equipment or software is required for integration and whether the robot supports the communication protocols used in your facility. Addressing compatibility upfront can prevent unexpected costs for modifications or system updates, saving time and resources.

SCALABILITY AND FLEXIBILITY

Consider the scalability of the robotic system. As your business grows, your robotic needs may evolve, requiring new functionalities or additional units. Opt for robots known for their flexibility in handling various tasks or those that can be easily upgraded with new capabilities. Investing in scalable and flexible systems can help prevent future bottlenecks and reduce the need for complete overhauls as your operation expands.

MAINTENANCE AND SUPPORT

Understanding the maintenance requirements and available support is essential when selecting a robot. Inquire about the maintenance schedule, availability of spare parts, and the technical support provided by the manufacturer. High maintenance costs can impact the total cost of ownership, so it’s also important to consider the availability of local service technicians who can perform repairs and regular maintenance to minimize downtime.

TOTAL COST OF OWNERSHIP

In addition to the initial purchase price, it’s crucial to evaluate the total cost of ownership, which includes installation, maintenance, training, and potential downtime costs. Consider energy consumption, consumables, and the need for regular software updates. Conducting a thorough cost analysis will enable a more informed decision by comparing the long-term financial impact of different robotic systems on your operations.

REGULATORY COMPLIANCE AND SAFETY STANDARDS

Ensure that any robot being considered meets all relevant regulatory and safety standards for your industry and region. This is particularly critical in sectors like healthcare, food processing, and automotive manufacturing, where safety and precision are paramount. Non-compliance can result in legal issues, fines, or operational disruptions, which can be costly. Verifying certifications such as ISO standards or specific industry compliance is essential to safeguard operations and ensure worker safety.

ENVIRONMENTAL CONSIDERATIONS

Environmental factors like temperature, humidity, dust, and chemical exposure can significantly affect a robot’s performance and lifespan. It is important to select a robot designed to withstand the specific conditions of its operating environment. For instance, robots in heavy industrial settings may require robust construction and protective measures against heat and particulates, while cleanroom robots need to be designed to prevent contamination.

STAFF TRAINING AND ADAPTATION

Assess the level of training your staff will require to operate and maintain the new robotic system. Determine whether your team has the necessary skills or if additional hiring or training will be needed. The ease of use of the robotic system and the availability of vendor training programs should also be considered. Properly trained staff can enhance productivity and minimize downtime caused by operational errors.

FUTURE-PROOFING TECHNOLOGY

Invest in robotic technology that can adapt to future advancements. Consider whether the system supports machine learning, is adaptable to new software updates, and is compatible with emerging technologies. Choosing a robot that can be upgraded ensures its longevity and protects your investment.

RETURN ON INVESTMENT (ROI)

Evaluate the expected return on investment (ROI) for the robotic system by analyzing productivity gains, cost savings from reduced labor, and improvements in quality and consistency. A clear understanding of the financial impact and payback period will help justify the investment and ensure the robot aligns with your business objectives. Proper financial planning is essential to ensure the robot positively contributes to your bottom line.

For more information, please visit: https://www.kassowrobots.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech